As 3D concrete printing (3DCP) becomes more widely used, understanding building codes and regulations is crucial for contractors, developers, and architects. WolfPack 3DCP provides advanced printers and materials, but compliance with local, national, and international construction standards ensures safety, legality, and structural integrity of every project.

In this guide, WolfPack 3DCP covers essential regulations, challenges, and strategies for building 3D-printed structures safely and legally.

Why Building Codes Matter for 3DCP

Building codes exist to ensure:

- Safety: Structural integrity and fire resistance.

- Durability: Long-lasting construction under environmental stresses.

- Accessibility: Compliance with legal and urban planning requirements.

- Sustainability: Efficient energy use and eco-friendly materials.

3DCP is still an emerging construction method, which means codes are evolving. WolfPack 3DCP works closely with regulatory frameworks to ensure all printed structures meet industry standards.

Current Status of 3DCP Regulations Worldwide

United States

- 3D-printed structures must comply with International Building Code (IBC) and Local Municipal Codes.

- Structural and fire testing is required for new concrete mixes.

- WolfPack 3DCP printers and materials meet ASTM and ICC-ES standards for construction compliance.

Europe

- Countries like the Netherlands, Germany, and Italy are early adopters of 3DCP regulations.

- Standards focus on load-bearing walls, material strength, and energy efficiency.

- WolfPack 3DCP offers support to ensure adherence to European CE certifications.

Asia

- China and India are piloting regulatory frameworks for 3D-printed affordable housing.

- Requirements often include seismic safety, thermal insulation, and structural stability.

Middle East & Africa

- Some governments support 3DCP for low-cost housing with compliance guidelines for durability and safety.

- WolfPack 3DCP assists in adapting printers and materials for regional regulations.

Key Components of 3DCP Compliance

1. Material Testing

Concrete mixes must be tested for:

- Compressive strength

- Layer adhesion

- Setting time

- Fire resistance

- Freeze-thaw durability

WolfPack 3DCP uses certified materials designed for real-world construction standards.

2. Structural Engineering

3D-printed walls must withstand:

- Load-bearing requirements

- Wind pressure

- Seismic activity (where applicable)

Licensed engineers can certify that the design meets local building codes.

3. Fire Safety & Insulation

Printed homes must comply with fire safety standards, including:

- Flame resistance

- Smoke emission limits

- Heat insulation properties

WolfPack 3DCP materials are tested for fire safety compliance.

4. Electrical and Plumbing Integration

3DCP structures need proper conduits for utilities. Codes require:

- Safe spacing for wiring

- Compliance with plumbing standards

- Accessibility for inspections

5. Environmental Compliance

Some regions require sustainable practices, such as:

- Using low-carbon concrete

- Minimizing construction waste

- Meeting energy efficiency standards

WolfPack 3DCP printers reduce waste and support green construction goals.

Challenges with 3DCP Regulations

Despite progress, the industry faces challenges:

- Lack of universal standards – Regulations differ between countries and regions.

- Testing requirements – Each new concrete mix must pass structural and safety tests.

- Permitting delays – Authorities may be unfamiliar with 3DCP technology.

- Integration of traditional systems – Electrical, plumbing, and HVAC must comply with existing codes.

WolfPack 3DCP mitigates these challenges by providing certified material guidance, design validation, and technical support for code-compliant construction.

Best Practices for 3DCP Compliance

- Collaborate with licensed engineers – Ensure printed designs meet structural codes.

- Use certified concrete mixes – WolfPack 3DCP offers materials tested for safety and durability.

- Maintain documentation – Keep records of prints, material batches, and inspections.

- Plan utility integration – Design channels and cavities according to local codes.

- Stay updated on regulations – Laws are evolving as 3DCP becomes mainstream.

WolfPack 3DCP Support for Regulatory Compliance

WolfPack 3DCP provides a full ecosystem for code-compliant construction:

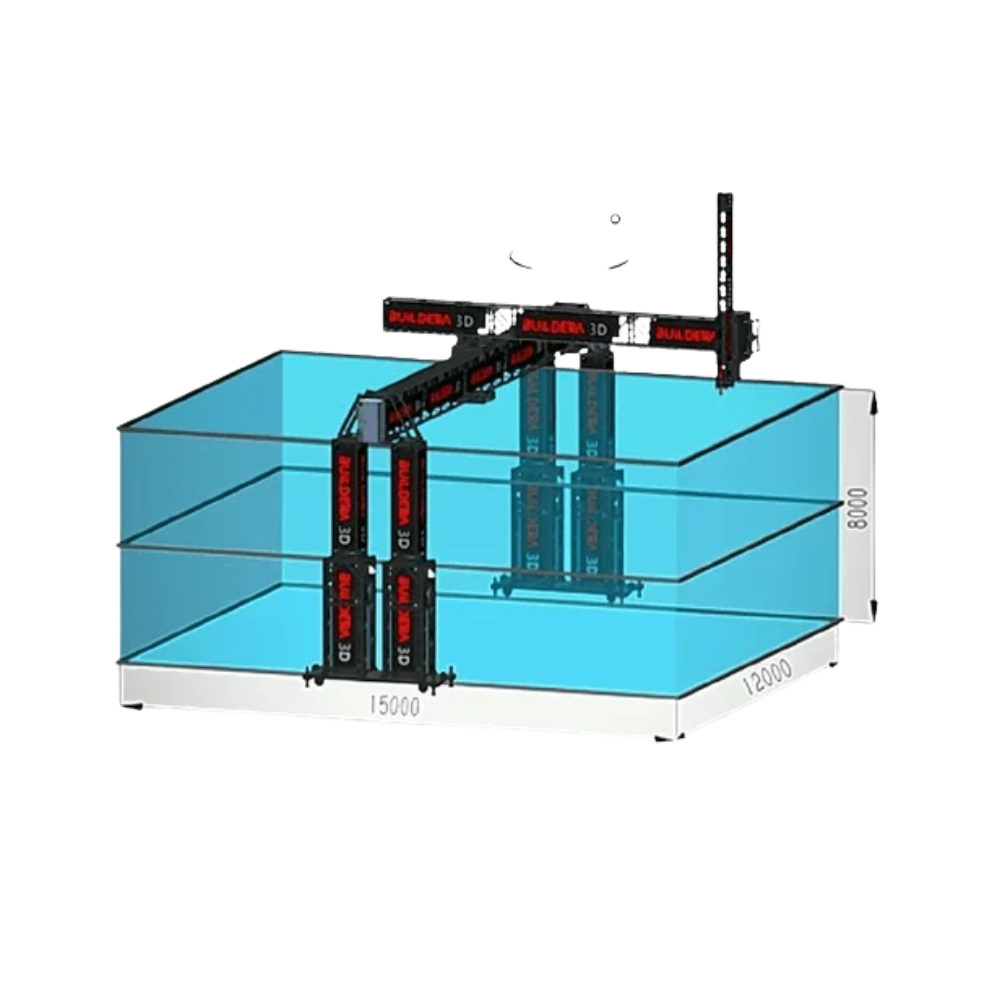

- Industrial-grade printers designed for consistent and certified prints.

- Material formulations tested for structural, thermal, and fire standards.

- Full training on operating 3DCP machines within legal guidelines.

- On-site support to meet local construction inspections and approvals.

- Documentation assistance for permitting and regulatory approvals.

This ensures that builders can adopt 3DCP confidently without risking non-compliance.

Future of 3DCP Regulations

Experts anticipate:

- Global standardization – Unified guidelines for 3D-printed structures.

- Faster approvals – Governments streamlining processes for emergency housing and low-cost projects.

- Sustainability incentives – Tax benefits and grants for green construction using 3DCP.

- Integration with smart city regulations – 3D-printed homes incorporating IoT, energy management, and green infrastructure.

WolfPack 3DCP is ready to guide clients through these upcoming changes with adaptable technology and expertise.

Conclusion

3D concrete printing is revolutionizing construction, but adhering to building codes and regulations is crucial. WolfPack 3DCP not only provides industrial-grade printers and advanced materials but also ensures that every project meets legal, safety, and sustainability standards.

By combining innovation with compliance, WolfPack 3DCP empowers builders to confidently adopt 3DCP technology and create durable, modern, and fully approved structures worldwide.