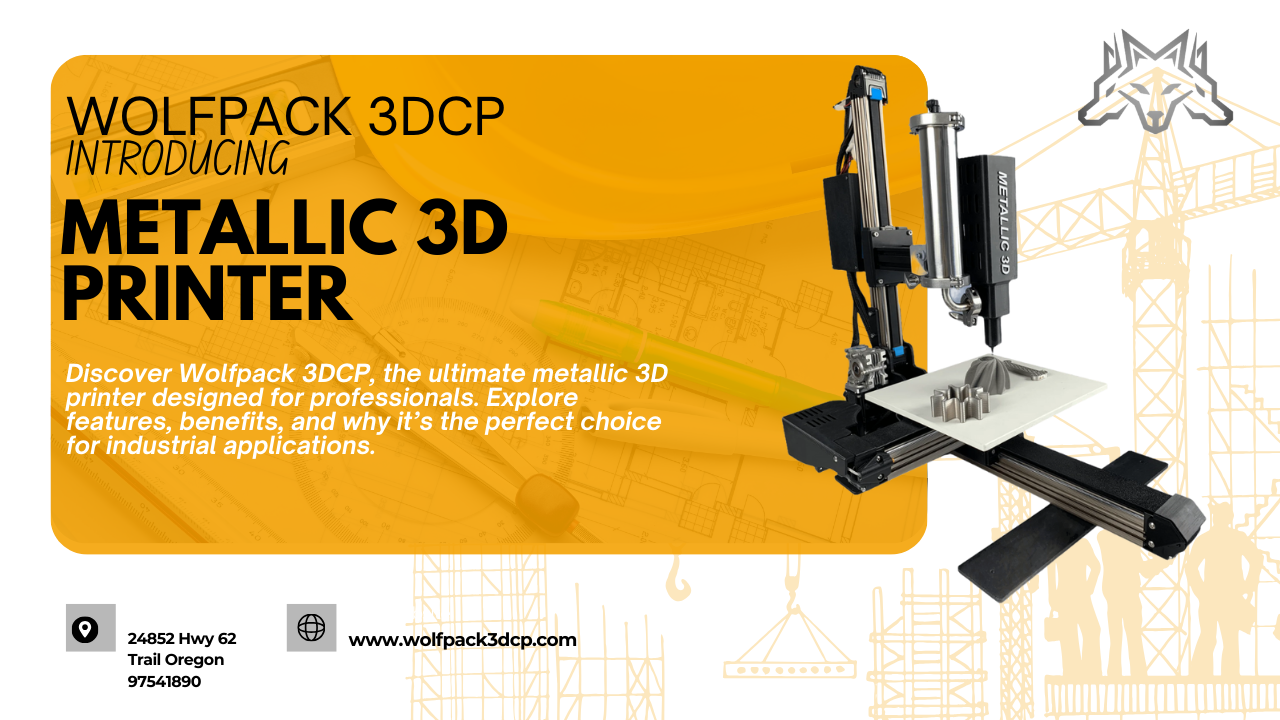

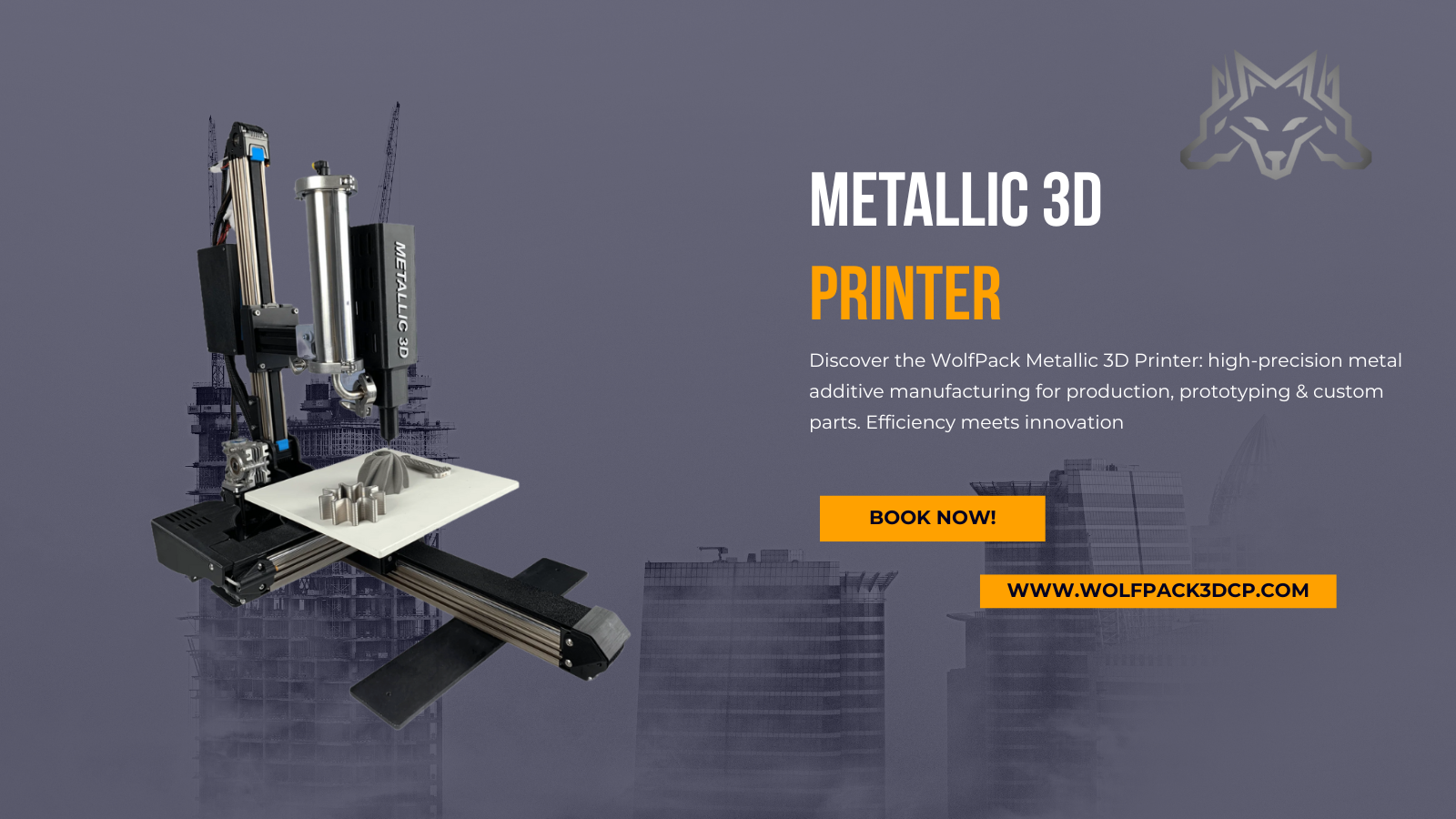

Investing in a metal 3D printer is a big step for any business — whether you’re in manufacturing, prototyping, or construction. The right printer can help you cut production time, reduce waste, and achieve unmatched precision.

But before making that investment, there are a few critical things every buyer should check. Here’s a guide to help you make an informed decision before purchasing your metallic 3D printer.

1. Printer Technology & Build Method

Not all metal 3D printers use the same process. Common methods include DMLS (Direct Metal Laser Sintering), SLM (Selective Laser Melting), and Binder Jetting.

Each method offers different advantages:

- DMLS/SLM → Best for high-density, strong parts.

- Binder Jetting → More cost-efficient for bulk production.

Always verify what technology your printer uses and whether it aligns with your project’s needs — from precision parts to large-scale metal structures.

2. Material Compatibility

Different printers support different metal powders such as stainless steel, aluminum, titanium, or copper.

Before investing, check:

- Which metal types are supported?

- Are the powder materials easily available?

- Does the printer require proprietary materials or allow third-party use?

Choosing a machine with versatile material support ensures flexibility for future projects and cost efficiency over time.

3. Print Accuracy & Build Volume

The resolution and build size of your 3D printer define its performance.

If your work demands precision prototypes, focus on micron-level accuracy.

If you’re printing industrial or construction parts, build volume and layer consistency matter more.

Always check:

- Layer resolution (µm)

- Build chamber size

- Repeatability and calibration options

A reliable industrial 3D printer offers both large capacity and precise accuracy.

4. Total Cost of Ownership

The purchase price is only part of the investment. Don’t overlook:

- Material costs (metal powders)

- Energy consumption

- Maintenance and calibration needs

- Software licensing or training

When comparing printers, calculate cost per print and annual operating cost. Sometimes, a slightly higher upfront investment saves you much more in long-term efficiency.

5. Support, Service, and Upgradability

A great printer is only as good as its support system.

Before purchasing, check if the manufacturer offers:

- On-site training and setup

- After-sales technical support

- Regular firmware or software updates

Future-proof your investment by choosing a brand that provides upgrade options — so your printer grows with your production demands.

Conclusion: Make Smart, Informed Investments

Metallic 3D printing is transforming industries — but only if you choose the right equipment.

Before you buy, focus on technology, materials, accuracy, total cost, and service.

At WolfPack 3DCP, our Metallic 3D Printer is built with these essentials in mind — designed to deliver industrial precision, long-term reliability, and scalable performance.