Metal fabrication is undergoing a revolution. With demands for faster lead-times, deeper customization, and stronger materials, the shift from traditional subtractive methods to additive is no longer optional — it’s imperative.

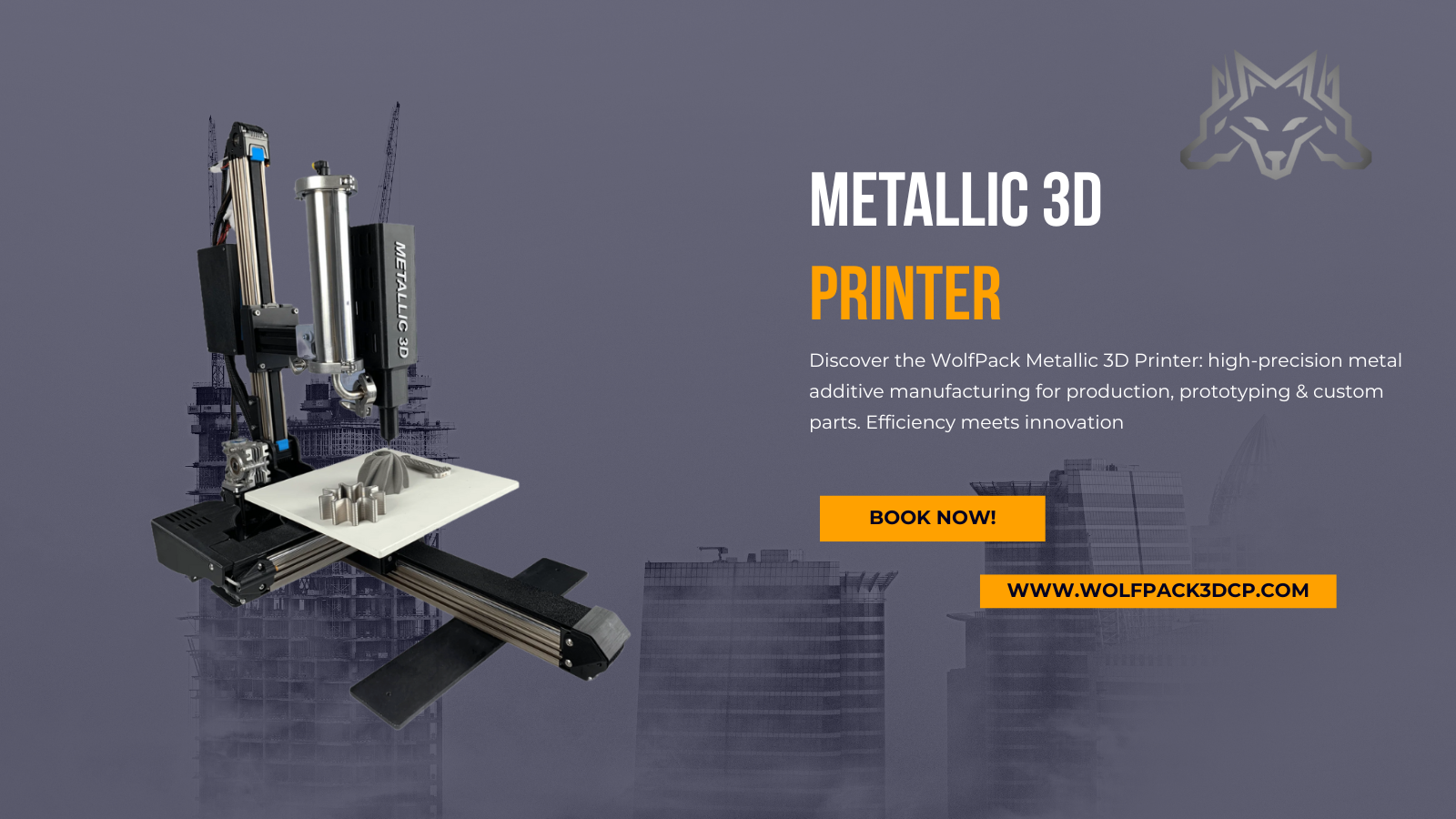

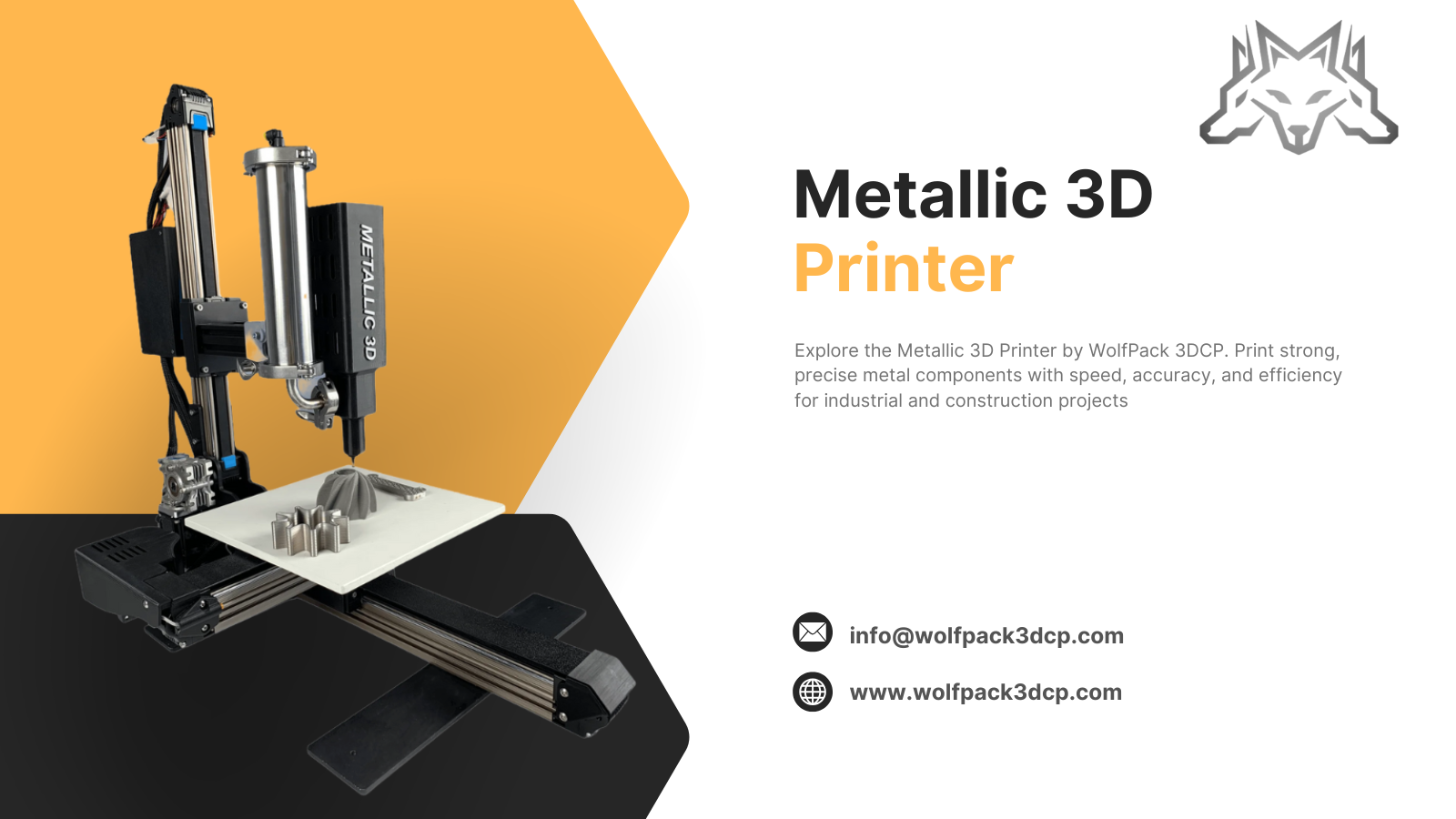

The WolfPack Metallic 3D Printer brings this transformation to your workshop, manufacturing floor, or prototyping lab. It’s not just a machine — it’s your gateway into high-precision, high-flexibility metal manufacturing.

1. Why Metal 3D Printing Matters

In metal manufacturing, traditional machining and casting methods come with significant challenges:

- Waste from removed material

- Limitations on complex geometries

- Long setup and tooling times

Metal additive manufacturing (AM) eliminates many of these bottlenecks. You can produce: - Intricate lattice structures

- Internal channels and optimized weight structures

- On-demand small-batch parts without expensive tooling

As the WolfPack site explains, the Metallic 3D Printer supports industrial-grade output for production or prototyping.

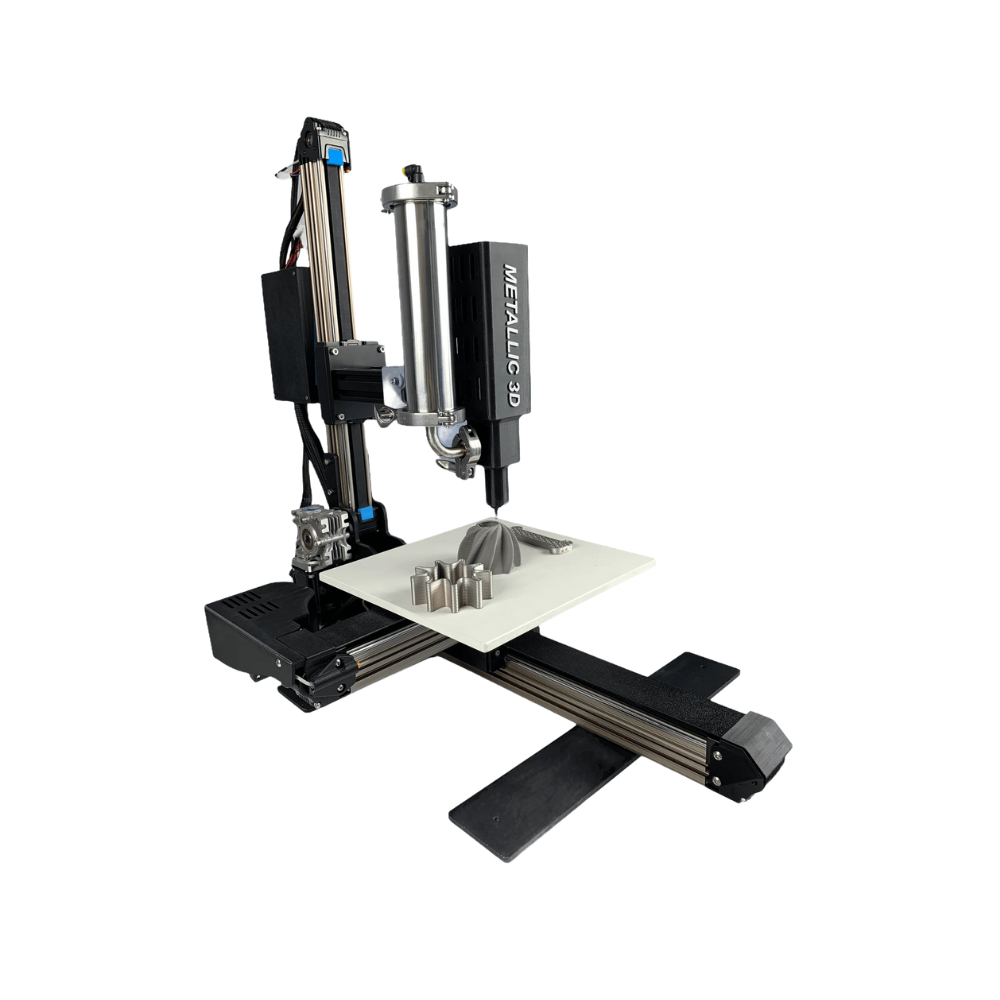

2. Introducing the WolfPack Metallic 3D Printer

Designed for versatility and performance, this machine is built to deliver real manufacturing value. From the product listing:

- Build volume: ~ 280 × 280 × 325 mm

- Build rate: Up to 1,000 mL/hr for multiple materials

- Material versatility: including stainless steel, titanium, copper, Inconel, ceramics and more.

These features mean you’re not limited to simple parts — you’re capable of real, production-ready components.

3. Top Reasons to Choose This Metallic 3D Printer

3.1 High Precision, Complex Geometries

When your parts demand internal channels, optimized structure, or bespoke geometry, traditional methods struggle. This printer excels at delivering those complex shapes with high fidelity, enabling design freedom.

3.2 Broad Material Support

From high-strength alloys like titanium and Inconel to specialty ceramics and even precious metals, this platform gives you flexibility to choose the right material for the job — whether aerospace-grade tooling or customized machine components.

3.3 Rapid Turnaround & Production Efficiency

Large build volume combined with high build rate means shorter lead times. Whether prototyping or small-batch manufacturing, you’ll benefit from faster cycles and lower per-part cost.

3.4 Lower Waste & Sustainable Manufacturing

Additive processes inherently reduce waste compared to subtractive machining. This printer takes that further by supporting efficient material usage and multiple materials in one platform — aligning with sustainable manufacturing goals.

3.5 Future-Proof Manufacturing Floor

As manufacturing continues to shift toward digital workflows, your investment in this printer becomes a strategic asset. It fits into smart factory plans, supports rapid iteration and adapts to evolving material demands.

4. How It Works — Workflow Overview

- Load the metal feedstock/pre-alloyed powder or filament depending on setup.

- Prepare the part geometry using CAD/AM software and export to STL/AM format.

- Set build parameters (layer thickness, support structures, material type).

- Initiate the print — the machine builds layer by layer, handling complex features.

- Post-processing (heat treatment, surface finishing) as required.

- Inspect and deploy the part into production.

This streamlined workflow means you shift from design to part in far less time than traditional cycles.

5. Ideal Applications

- Aerospace & Defense: parts with complex internal cooling channels, lightweight structures.

- Tooling & Manufacturing: custom jigs, fixtures, inserts with optimized shapes.

- Medical Devices: implants or components with tailored geometry and biocompatible metals.

- Research & Development: materials experimentation, multi-material builds, rapid prototyping.

- Luxury & Custom Goods: small-batch high-value items using specialty metals.

6. Why WolfPack 3DCP Stands Out

WolfPack isn’t just a machine vendor — they offer systems designed for integration, industrial performance and real-world manufacturing. The Metallic 3D Printer reflects that:

- Industrial-grade build and support system

- Versatility across materials and applications

- Proven build volume and rate for real output

By choosing WolfPack, you’re aligning with a provider who understands the full additive manufacturing workflow — not just the machine.

Conclusion

The WolfPack Metallic 3D Printer is more than an add-on to your manufacturing arsenal — it’s a strategic leap toward modern, flexible, high-precision metal production.

If you’re ready to unlock complex geometries, bring production in-house, and reduce time-to-part, this machine is your gateway.

🔗 Visit: WolfPack Metallic 3D Printer wolfpack3dcp.com

💬 FAQs

Q1. What materials can this printer handle?

It’s compatible with a broad range of metals (stainless steel, titanium, copper, Inconel) and even ceramics and specialty materials.

Q2. What is the maximum build volume?

Approximately 280 × 280 × 325 mm.

Q3. Is this suitable for production, or just prototyping?

Absolutely suitable for both — high build rate and industrial specs make it production-capable.

Q4. How does it compare to traditional manufacturing?

It offers design freedom, lower waste, faster turnaround and better material use compared to machining or casting.

Q5. What support and service comes with the machine?

WolfPack provides product documentation, material support and service infrastructure to ensure your printing workflow runs smoothly.