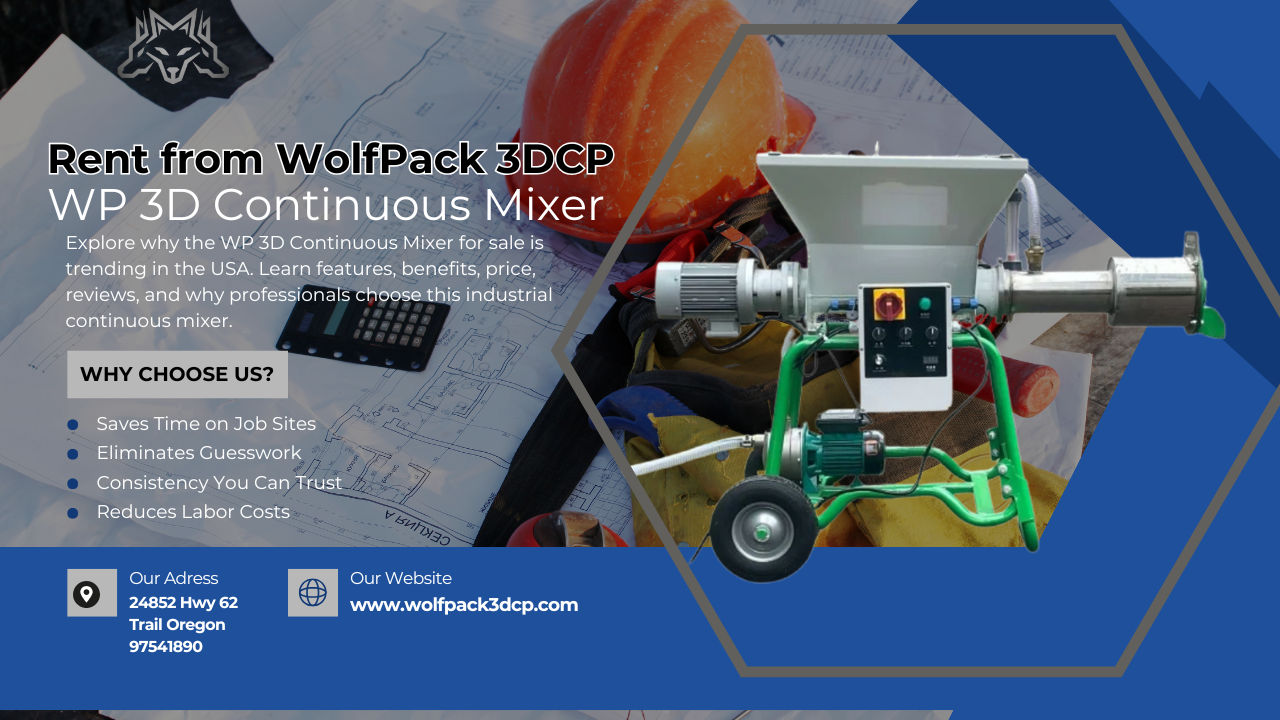

Contractors want faster, automated, and more accurate mixing solutions.

Traditional mixers cause inconsistent hydration, wasted material, and delays. But the WP 3D Continuous Mixer from WolfPack 3DCP solves these issues with advanced automation and precision engineering—ideal for 3D printing, masonry, grouting, and heavy-duty mortar work.

What Is the WP 3D Continuous Mixer?

The WP 3D Continuous Mixer is an industrial-grade mortar mixing station designed for high-performance, continuous-flow mixing.

It maintains perfect water-to-powder ratios, ensures consistent material quality, and eliminates the common errors seen with traditional batch mixers.

Price: $6,600

The mixer integrates seamlessly with the WP 3D Pump and Sprayer, creating a complete workflow for 3D concrete printing and construction finishing.

Components / Materials Inside the Machine

The mixer includes high-quality mechanical and electronic components. These “ingredients” make up the internal system:

Mechanical Components

- Heavy-duty powder-coated steel housing

- Stainless steel mixing blades

- Reinforced 60L hopper

- High-flow output chute (0–500 RPM)

Electrical & Motor Components

- 3 kW DC brushless motor

- 220V system with NEMA 6-50P connector

- Precision servo motors

- Control panel with speed dial (not belt-driven)

Automation Components

- Built-in automated water dosing unit

- Hydration sensors for ratio accuracy

- Quick-clean flushing system

- Super Sack compatibility system

These components ensure durability, precision, and long-term reliability.

Key Features

- ✔ 220V, 3 kW DC Brushless Motor

- ✔ 60L Capacity Hopper

- ✔ 0–500 RPM Output Flow

- ✔ Automated Water Dosing

- ✔ Adjustable Dial-Based Speed Control

- ✔ Easy-Clean System

- ✔ Super Sack Compatible

Built for industrial usage, the WP 3D Continuous Mixer offers smooth material quality—critical for 3D concrete printing and professional mortar applications.

Why Contractors Search for “WP 3D Mortar Mixing Station Price”

Google Trends shows increased search behavior around:

- “3D concrete printing mixer buy”

- “concrete mixer for 3D printing sale”

- “continuous concrete mixer 220V 3 kW”

This demand is driven by the growth of automated 3D construction, which requires:

- High-quality mix control

- Consistent hydration

- Fast output

- Industrial reliability

The WP 3D Continuous Mixer matches all these requirements and is priced competitively for USA professionals.

Benefits of the WP 3D Continuous Mixer

1. Maximum Productivity

Continuous mixing eliminates downtime between batches.

2. Perfect Consistency

Automated dosing ensures every mix meets exact hydration requirements.

3. Best for 3D Printing

Smooth flow and uniform texture produce clean, precise layers.

4. Lower Labor Costs

One operator can manage the entire mixing process.

5. Long-Term Durability

Built with industrial-grade steel and brushless motors.

6. Global Availability

WolfPack 3DCP offers WP 3D mixer shipping , ideal for U.S. and international projects.

User Reviews

⭐ Jonathan M. – California, USA

“I checked many options before buying, but the WP 3D mortar mixing station price made sense for the features and durability. It works perfectly with our 3D printer.”

⭐ Rosa F. – New York, USA

“Super Sack compatibility is a game changer. We save a lot of time and minimize spills.”

⭐ Liam S. – Colorado, USA

“Reliable, fast, and consistent. The difference in mix quality is huge.”

Who Should Buy This Mixer?

Ideal for:

- 3D concrete printing companies

- Construction contractors

- Masonry professionals

- Grouting crews

- Plaster and stucco service providers

- Industrial material mixing operations

If you need precise, continuous material flow—this machine is built for you.

How It Works

- Pour dry material into the hopper.

- Automated sensors deliver the correct water amount.

- The mixer blends the material using a high-power 3 kW motor.

- Output flow delivers perfectly mixed mortar at your preferred RPM.

- Use the quick-clean system for fast jobsite maintenance.

Frequently Asked Questions

1. What is the WP 3D mortar mixing station price?

The price is $6,600.

2. Is the mixer suitable for 3D concrete printing?

Yes, it delivers ideal consistency for 3D printing applications.

3. Can it be used for heavy-duty mortar projects?

Absolutely, it is built for industrial mortar mixing.

4. How much material can it hold?

It features a 60-liter hopper capacity.

5. Does it require complicated cleaning?

No, the built-in cleaning system makes the process simple and fast.

Conclusion

The increasing demand for 3D printing equipment and automated mortar systems explains why so many contractors search for “WP 3D mortar mixing station price”. Offering power, precision, and automation, the WP 3D Continuous Mixer stands out as a top-performing solution in the USA market.

If you’re ready to upgrade your mixing technology:

👉 See more equipment → https://wolfpack3dcp.com/shop/