3D concrete printing (3DCP) is transforming modern construction by replacing slow, labor-intensive building processes with automated, digital, and highly precise technology. WolfPack 3DCP specializes in industrial-grade machines that allow contractors, developers, and builders to print walls, structures, and even entire homes with remarkable speed and accuracy.

In this complete guide, WolfPack 3DCP explains what 3D concrete printing is, how it works, and why it has become one of the most powerful innovations in the global construction industry.

What Is 3D Concrete Printing?

3D concrete printing is an automated construction technique that uses a large robotic printer to deposit layers of specially engineered concrete based on a digital building model. Unlike traditional construction that requires formwork, manual bricklaying, and large labor teams, 3DCP creates structures directly from a computer-generated design.

A concrete 3D printer extrudes material layer by layer, forming precise walls and architectural features. The process eliminates errors, speeds up construction, and significantly reduces labor and waste. WolfPack 3DCP systems are engineered to deliver industrial reliability, smooth extrusion, and strong structural bonding for real-world projects.

How 3D Concrete Printing Works (Step-by-Step)

Although the technology looks futuristic, the workflow is simple and highly efficient:

1. Digital Design Creation

Architects or designers create a 3D building model using CAD or BIM software. The file includes dimensions, wall thickness, openings, and structural layouts.

2. Slicing the Model

The digital model is converted into thousands of horizontal layers, similar to slicing in traditional 3D printing. This tells the printer exactly how to build the structure.

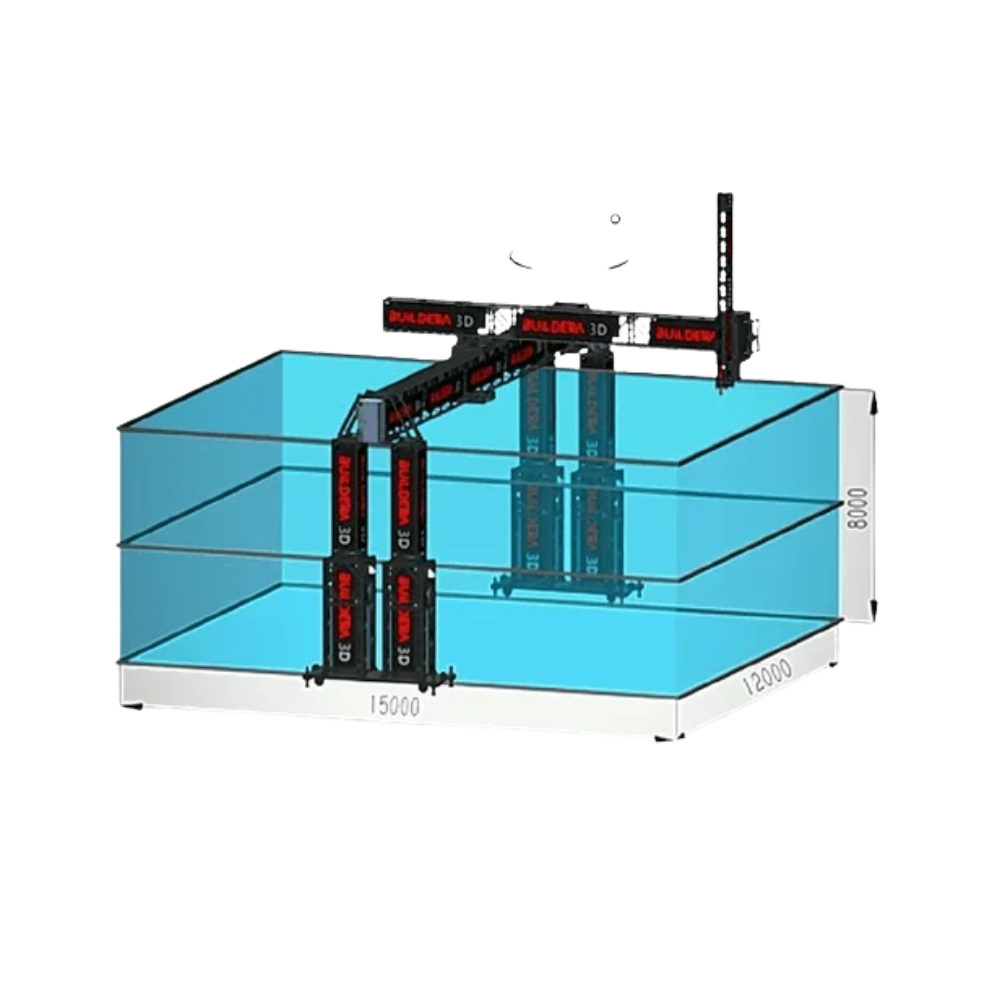

3. Preparing the Printer

WolfPack 3DCP printers are calibrated, leveled, and connected to the concrete pumping system. The concrete mixture is prepared based on project requirements.

4. Layer-by-Layer Printing

The printer nozzle extrudes concrete continuously as it moves along a programmed path.

The layers stack up to form external and internal walls with exceptional precision.

5. Structural and MEP Integration

Rebar, conduits, insulation, and other elements can be incorporated during or after printing.

6. Final Finishing

After printing, workers install roofing, doors, windows, electrical wiring, plumbing, and finishing materials.

This hybrid workflow—automation + traditional finishing—creates durable, high-quality homes in record time.

Why 3DCP Is Changing the Global Construction Industry

Traditional construction faces challenges such as labor shortages, long timelines, unpredictable costs, and material waste. 3D concrete printing solves these problems by offering:

- 60–70% faster construction

- Up to 50% labor reduction

- Lower material waste

- Digitally controlled precision

- Design freedom for architects

With WolfPack 3DCP systems, contractors can handle more projects with less labor while delivering stronger and more sustainable structures.

Why Choose WolfPack 3DCP for 3D Concrete Printing?

WolfPack 3DCP stands out as one of the most reliable and advanced manufacturers in the concrete printing industry. Our solutions include:

✔ Industrial-Grade Concrete Printers

Built for durability, stability, and 24/7 construction performance.

✔ USA-Engineered Technology

High-quality components, precision calibration, and superior build quality.

✔ Fast & Accurate Printing

Smooth extrusion, clean layers, and strong structural bonding.

✔ Training & Full Technical Support

We guide your team from installation to your first printed building.

✔ Affordable Pricing + Rental Options

We make it possible for small and large contractors to adopt 3DCP without major financial risk.

Whether you’re a developer, contractor, architect, or construction startup, WolfPack 3DCP provides everything you need to become a leader in modern construction.

Applications of 3D Concrete Printing

3DCP is being used for a wide range of building applications, such as:

- Residential homes

- Low-cost housing

- Emergency shelters

- Office buildings

- Boundary walls

- Architectural elements

- Commercial infrastructure

- Complex design structures

With the rapid growth of the technology, entire communities and commercial areas can be printed at lower cost and in far less time than traditional methods.

Benefits of 3D Concrete Printing with WolfPack 3DCP

1. Speed

Print homes in days instead of months.

2. Strength

Engineered concrete mixes provide high compressive strength and long-lasting durability.

3. Cost Efficiency

Lower labor costs, fewer materials, and predictable project budgets.

4. Sustainability

Reduced waste, lower carbon footprint, and energy-efficient structures.

5. Accuracy

Digitally controlled precision ensures walls are straight, strong, and consistent.

6. Design Flexibility

Curved walls, unique shapes, and complex architecture are easy to print.

Is 3D Concrete Printing the Future of Construction?

Absolutely. As more countries adopt digital construction methods and push for faster, greener, and more affordable housing, 3DCP is becoming the preferred building solution.

WolfPack 3DCP is leading the movement by supplying industrial-grade printers, advanced materials, and complete training programs to help companies adopt this revolutionary method.

Conclusion

3D concrete printing is reshaping the future of construction with automation, efficiency, and innovation. Whether you want to reduce costs, increase productivity, or build modern housing projects, WolfPack 3DCP offers the technology and expertise to help you succeed.