3D concrete printing, commonly known as 3DCP, is one of the most transformative innovations in the construction industry. Today, companies like WolfPack 3DCP are pushing the boundaries of automated building, but this groundbreaking technology has evolved over decades of research, experimentation, and engineering progress.

Understanding the history of 3DCP helps builders, developers, and architects appreciate how far construction technology has come — and where it’s headed next. In this article, we trace the origins, milestones, and global developments that shaped modern 3D concrete printing.

Early Origins of 3D Printing (1980s–1990s)

Before 3D concrete printing became a possibility, the general concept of additive manufacturing had to be invented. The 1980s marked the beginning of the 3D printing revolution.

1984 — The First 3D Printer

Chuck Hull invented stereolithography (SLA), creating the world’s first working 3D printer. Although this machine used resin, not concrete, it introduced the core idea:

building objects layer by layer from a digital model.

1990s — Additive Manufacturing Expands

Engineers began experimenting with new materials such as plastics, metals, ceramics, and powdered composites. The construction industry soon realized the potential for printing large-scale structures.

These developments laid the foundation for concrete 3D printing.

The Birth of Large-Scale Concrete Printing (2000–2010)

The early 2000s marked a major turning point as researchers began exploring how to adapt additive manufacturing to construction.

2004 — The Contour Crafting Breakthrough

Professor Behrokh Khoshnevis introduced Contour Crafting, the first large-scale automated construction concept. His research showed that buildings could be printed using cementitious materials and robotics.

This was the first real proof that printing houses was possible.

2005–2010 — Experimental Construction Printing

Across Europe and Asia, universities and engineering groups explored:

- concrete extrusion techniques

- pumpable cement mixtures

- robotic gantry systems

- early slicing software for construction

Although still in prototype stages, the idea of 3D-printed buildings gained global attention.

Rise of Modern 3DCP Systems (2010–2020)

Once the technology matured, concrete printing systems rapidly evolved into commercial construction tools.

2012–2015 — First 3D Concrete Print Projects

During this period, researchers and private companies successfully printed:

- small houses

- walls and structural components

- architectural elements

- demonstration shelters

This proved that 3DCP was not just a lab experiment — it was becoming a real construction solution.

2016 — The Commercialization Wave Begins

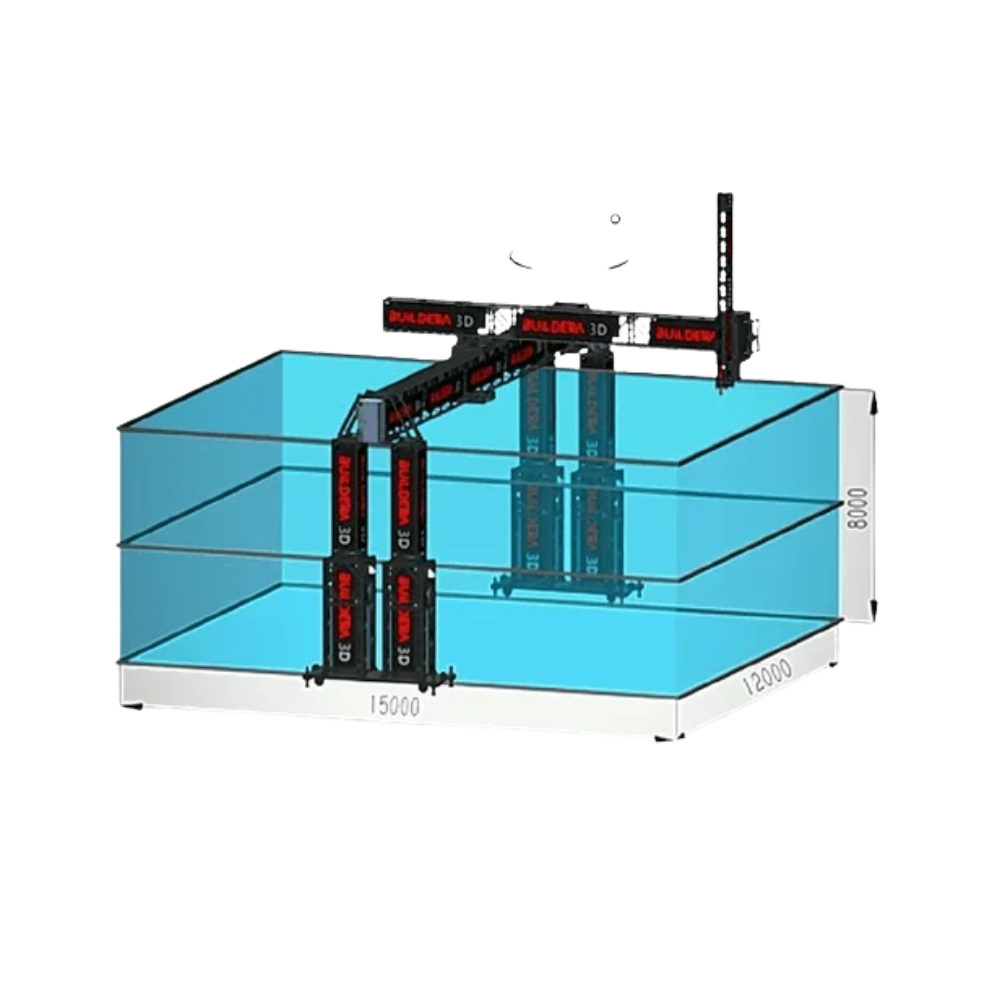

Companies worldwide started launching their own concrete 3D printers. Gantry-based and robotic arm systems became more refined, with better precision, stability, and printing speed.

2017–2020 — Global Adoption Accelerates

Several major milestones occurred:

- The world’s first 3D-printed communities were planned.

- Governments began funding affordable housing projects using 3DCP.

- Engineers developed new concrete mixes with faster setting and higher strength.

- Codes and regulations started forming to guide printable construction.

Technology was finally ready for real-world use — and companies like WolfPack 3DCP prepared to shape the future of automated building.

The Modern Era of 3DCP (2020–Present)

The last few years have seen explosive growth in 3D concrete printing. With labor shortages, rising construction costs, and demand for affordable housing, 3DCP is now viewed as one of the most promising building technologies.

Key Advancements in Recent Years

- High-speed industrial printers

- Improved layer bonding and pump systems

- GPS, laser-leveling, and automated calibration

- Large-scale gantry printers capable of printing full homes

- Software that integrates design, slicing, and printing control

- Printable concrete mixes with exceptional compressive strength

WolfPack 3DCP has played a major role in this advancement by launching durable, efficient, and accessible printing systems engineered for practical construction environments.

How WolfPack 3DCP Is Shaping the Future

WolfPack 3DCP represents the new generation of building technology. Our systems are designed for real-world construction teams who want reliability, speed, and precision.

What Sets WolfPack 3DCP Apart?

✔ USA-engineered machines built for long-term durability

✔ Industrial-grade gantry systems for large-scale projects

✔ Advanced pumping and extrusion mechanisms

✔ High-strength printable concrete mixtures

✔ Comprehensive training and onsite support

✔ Affordable prices and rental options for contractors

By bridging innovation with practical construction needs, WolfPack 3DCP empowers builders to enter the world of automated construction with confidence.

Why the History of 3DCP Matters

Understanding the evolution of 3D concrete printing highlights why it’s becoming the leading technology for:

- low-cost housing

- emergency shelters

- residential communities

- commercial buildings

- modern architectural design

- sustainable construction

From early laboratory experiments to full-scale 3D-printed neighborhoods, the journey of 3DCP shows the power of engineering and digital automation.

Future Outlook: What Comes Next?

Experts predict massive growth for 3DCP over the next decade. The future includes:

- code-approved 3D-printed housing developments

- hybrid robotics and AI-assisted construction

- fully automated job sites

- eco-friendly concrete materials

- faster, taller, and more complex printed buildings

WolfPack 3DCP is committed to leading this next evolution by delivering cutting-edge printers and technology to builders worldwide.

Conclusion

The history of 3D concrete printing is a story of innovation, engineering progress, and global transformation. What began as a simple concept in the 1980s has become a powerful construction technology changing the world today.

WolfPack 3DCP stands at the forefront of this evolution — providing advanced machines, training, and support to help builders adopt the future of construction.