3D concrete printing (3DCP) is transforming the construction industry by enabling fast, automated, and precise building processes. While the technology looks highly advanced, the workflow behind it is simple, efficient, and extremely systematic. At WolfPack 3DCP, we specialize in delivering printers and systems built for real-world projects — from housing communities to commercial structures.

In this detailed guide, we break down exactly how 3D concrete printing works, step by step, and explain the entire workflow followed by professionals in the 3DCP industry.

Understanding the Core Concept of 3DCP

3D concrete printing is a form of additive manufacturing where a large robotic machine extrudes specially formulated concrete layer by layer. The printer follows a digital blueprint, eliminating the need for manual formwork, bricks, or traditional labor-intensive methods.

This process produces stronger, more consistent, and highly accurate structures while significantly reducing build time and cost.

The Complete Step-by-Step 3DCP Workflow

Below is the full construction process used by WolfPack 3DCP systems.

STEP 1 — Project Planning & Digital Design

Everything begins with a digital 3D model. Architects or designers create a CAD or BIM model that includes:

- wall thickness

- openings for windows and doors

- electrical and plumbing pathways

- structural requirements

- overall building layout

The model must be optimized for extrusion geometry. WolfPack 3DCP also supports complex shapes such as curves, angles, and organic forms.

STEP 2 — Slicing the Model Into Layers

Once the digital model is ready, it is imported into slicing software. This software converts the entire structure into thousands of thin horizontal layers.

The slicer determines:

- layer height

- extrusion speed

- print path

- nozzle travel route

- material output rate

This “layer-by-layer” file becomes the printer’s roadmap.

STEP 3 — Preparing the Construction Site

Before printing begins, a stable foundation must be prepared. This includes:

- leveling the ground

- placing the base foundation

- marking printer boundaries

- ensuring enough workspace for gantry movement

WolfPack 3DCP printers require minimal setup and can be assembled quickly on-site.

STEP 4 — Positioning & Calibrating the Printer

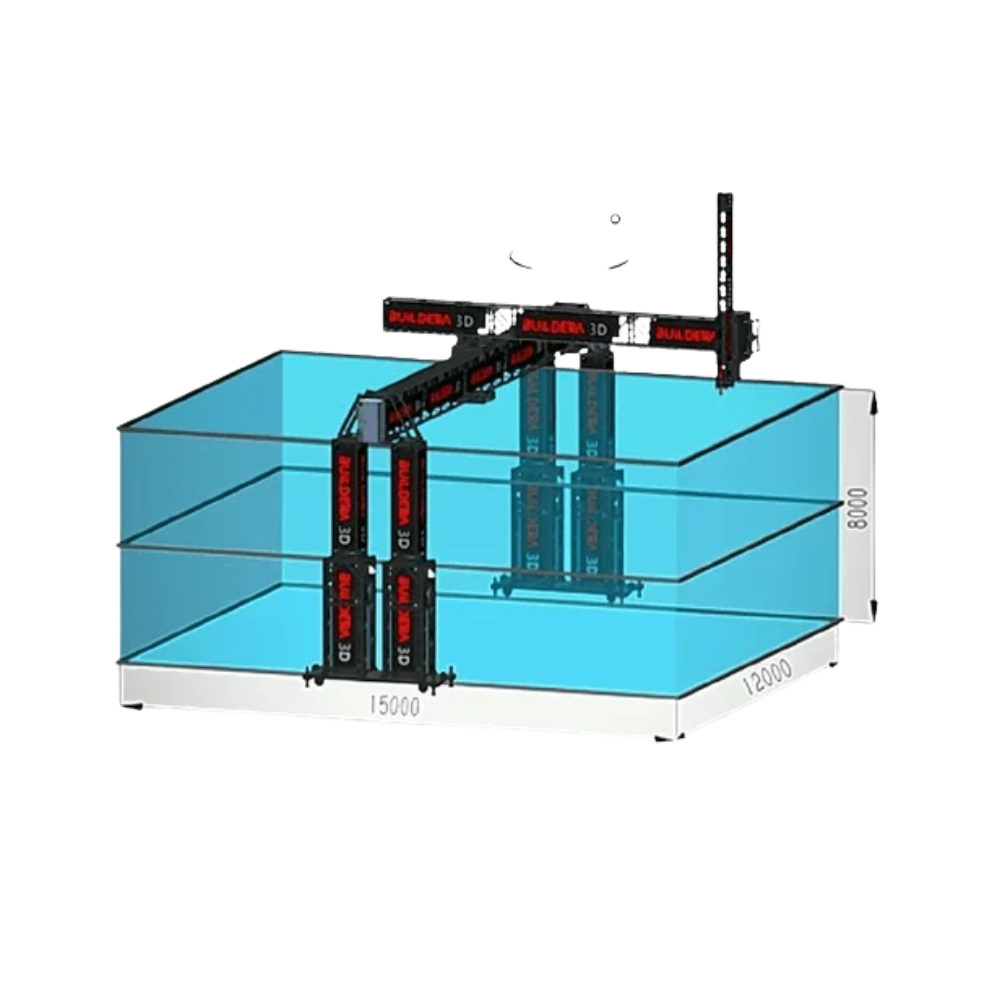

WolfPack 3DCP gantry printers are positioned over the foundation. Our systems include:

- automated leveling sensors

- precision calibration tools

- robust gantry frames

- high-torque motors for smooth movement

Calibration ensures the printer delivers perfect layer accuracy from the first pass to the final layer.

STEP 5 — Preparing the Material (Printable Concrete Mix)

3DCP concrete is not the same as traditional concrete. It must be:

- pumpable

- fast-setting

- high-strength

- consistent in viscosity

- optimized for bonding between layers

WolfPack 3DCP uses advanced mixtures designed for strong structural prints. The concrete is loaded into a continuous mixer and pumped to the printer via a hose system.

STEP 6 — Beginning the Layer-by-Layer Printing

This is where the real magic happens. The printer starts executing the sliced file and extrudes concrete through a controlled nozzle.

The nozzle moves along a predefined path:

- depositing material

- building each layer

- stacking layers to form walls

The precision is incredibly high, ensuring repeatability and accuracy in every print.

WolfPack 3DCP printers offer stable, vibration-free printing and consistent flow control, which results in smooth layers and strong bonding.

STEP 7 — Integrating Structural Elements

Depending on the design, the construction team may integrate:

- rebar

- vertical reinforcement

- insulation materials

- conduits for plumbing and electrical

These elements are added manually during pauses or specific print stages.

STEP 8 — Printing Internal & External Walls

3DCP machines print:

- internal partition walls

- external load-bearing walls

- curved architectural features

- insulation cavities

- reinforcement voids

Complex designs that would be difficult or expensive with traditional construction become much easier with 3DCP.

STEP 9 — Curing & Structural Setting

3DCP concrete cures at a controlled speed. Strong layer bonding ensures excellent compressive strength.

Curing time varies based on:

- mix design

- temperature

- humidity

- layer thickness

WolfPack 3DCP mixtures are engineered to harden quickly without compromising durability.

STEP 10 — Post-Printing Finishing Work

Once the walls are printed, the remaining construction steps include:

- installing roofing

- placing doors and windows

- electrical wiring

- plumbing

- insulation

- interior finishing

- exterior treatments

The major difference is that the entire wall structure is already printed, saving weeks or months of labor.

How Long Does 3DCP Construction Take?

One of the biggest advantages of 3DCP is speed. With WolfPack 3DCP printers:

- A single-story house can be printed in 24–48 hours

- Multi-room structures can be printed in days instead of weeks

- Large-scale projects can reduce timelines by 60–70%

For contractors and developers, this means faster project delivery and higher profitability.

Behind the Technology: What Powers 3DCP?

1. Gantry or Robotic Printer

Moves along X, Y, and Z axes to extrude the material.

2. High-Performance Pumping System

Supplies continuous concrete flow to the nozzle.

3. Printable Concrete Mix

Engineered for smooth extrusion and high-strength bonding.

4. Slicing Software

Converts designs into layered printing instructions.

5. Automated Controls

Precision sensors ensure accurate deposition and smooth printing.

WolfPack 3DCP integrates all these components into a reliable, construction-grade ecosystem.

Why WolfPack 3DCP Leads the 3DCP Workflow

WolfPack 3DCP offers cutting-edge machines that stand out due to:

- USA-engineered durability

- powerful extrusion and pump systems

- smooth, stable gantry movement

- fast printing speeds

- affordable pricing for all business sizes

- rental options for new companies

- full training and expert support

Whether you’re a startup or an established contractor, we provide everything you need to succeed in 3D printed construction.

Conclusion

The 3DCP process is a powerful combination of digital design, precision robotics, and advanced concrete materials. From slicing the model to printing the walls, every step is optimized for speed, accuracy, and structural strength.

WolfPack 3DCP is proud to deliver industrial solutions that make this modern construction method accessible to builders around the world.