As 3D concrete printing (3DCP) expands across the global construction industry, one of the most important questions builders ask is:

“Which type of 3D concrete printer should I choose?”

The answer depends on your project scale, budget, printing requirements, and long-term construction goals. At WolfPack 3DCP, we manufacture industrial-grade concrete printers engineered for durability, speed, and high-precision building. To help you understand the full landscape of available technologies, this guide covers every major type of 3DCP machine, their functions, advantages, and ideal use cases.

This is your complete, 1000+ word educational resource for selecting the right 3D concrete printer for your business.

Why Understanding 3DCP Machine Types Matters

Not all concrete printers work the same. The difference between machine types affects:

- print speed

- layer accuracy

- build volume

- mobility

- cost

- on-site flexibility

- maintenance requirements

Choosing the right system allows builders to complete projects faster, cut labor expenses, and achieve superior print quality.

WolfPack 3DCP specializes in gantry-based concrete printers, the most stable and popular systems used worldwide. But to give you a full understanding, let’s explore all types.

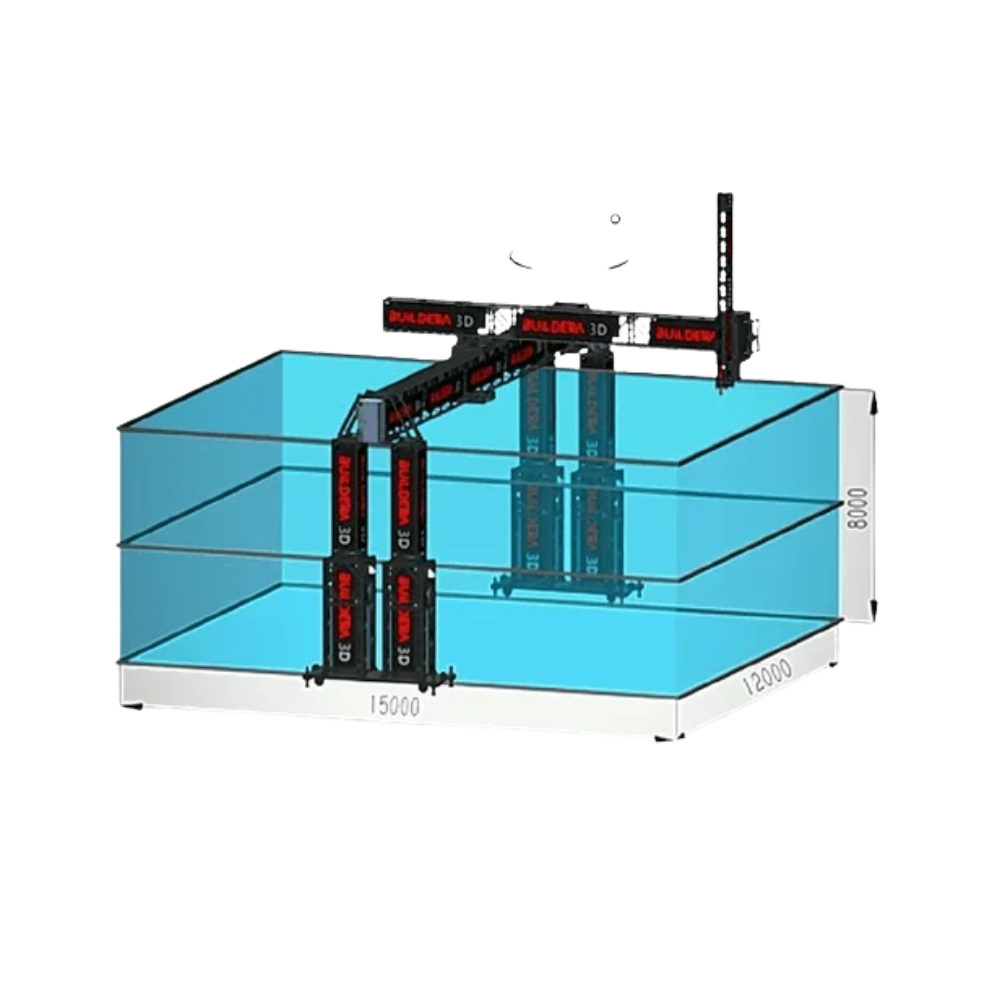

1. Gantry-Based 3D Concrete Printers

Overview

Gantry printers are the most widely used and most stable type of 3DCP machine. They operate using rails and beams that move along X, Y, and Z axes to extrude concrete with precision.

How It Works

A gantry frame surrounds the build area. The print head moves along the rails to deposit concrete layer by layer.

Advantages

✔ High precision

✔ Ideal for printing full homes

✔ Stable and vibration-free

✔ Large build volume

✔ Excellent for straight and curved walls

✔ Reliable for repetitive projects

Use Cases

- Single-story and multi-room homes

- Commercial offices

- Long boundary walls

- Housing communities

- Printed building components

WolfPack 3DCP Perspective

Our flagship machines are gantry-based because they offer the best balance of:

accuracy, speed, durability, and affordability for real-world construction.

2. Robotic Arm 3D Concrete Printers

Overview

Robotic arm printers use a multi-axis robotic arm, similar to those used in automotive factories, to extrude concrete in flexible directions.

How It Works

A 6–7 axis robotic arm precisely controls the nozzle, allowing free-form motion and artistic shapes.

Advantages

✔ Excellent for sculptural or curved designs

✔ High flexibility

✔ Can print from multiple angles

✔ Compact footprint

Limitations

✘ Smaller build area

✘ Lower vertical height

✘ Less stability for large homes

✘ Expensive for the construction industry

Use Cases

- Furniture

- Decorative walls

- Complex architectural pieces

- Small structures

Robotic arms are powerful but not ideal for full-scale house printing.

3. Mobile or Crane-Based 3DCP Systems

Overview

These are large crane-like machines that rotate, extend, and retract to extrude concrete.

Advantages

✔ Can move freely

✔ Useful for large, open job sites

✔ Print tall structures

Limitations

✘ Lower precision than gantry systems

✘ Higher maintenance

✘ Expensive

✘ Requires experienced operators

Use Cases

- Large infrastructures

- Outdoor construction

- Tall architectural walls

Not commonly used due to complexity.

4. Track-Mounted 3D Concrete Printers

Overview

This system uses a printer mounted on movable tracks that can shift around the site automatically.

Advantages

✔ Good mobility

✔ Can print long linear structures

✔ Useful for large-scale community layouts

Limitations

✘ Track setup required

✘ Lower print height

Use Cases

- Large housing communities

- Long fencing or walls

- Industrial facilities

5. Hybrid 3DCP Machines

Overview

Some companies combine gantry and robotic arm technology into hybrid systems for more flexibility.

Advantages

✔ Flexible printing options

✔ Can achieve both precision and creativity

Limitations

✘ High initial cost

✘ Complex maintenance

Use Cases

- Advanced architectural projects

- Mixed-design spaces

Comparing All 3DCP Machine Types

| Machine Type | Precision | Build Volume | Cost | Best For |

| Gantry | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | Medium | Full homes, communities |

| Robotic Arm | ⭐⭐⭐⭐ | ⭐⭐ | High | Design elements, art |

| Mobile Crane | ⭐⭐⭐ | ⭐⭐⭐⭐ | High | Large open sites |

| Track-Mounted | ⭐⭐⭐⭐ | ⭐⭐⭐ | Medium | Long linear builds |

| Hybrid | ⭐⭐⭐⭐ | ⭐⭐⭐ | High | Creative architecture |

Why Gantry Machines Are the Industry Standard

Gantry concrete printers are widely accepted as the most efficient and reliable method for printing homes. They offer:

- superior stability

- consistent extrusions

- excellent height capability

- large build volumes

- predictable printing results

These advantages make gantry systems the preferred option for government housing, private development, and commercial 3DCP projects worldwide.

WolfPack 3DCP Machine Technology

WolfPack 3DCP specializes in delivering industrial-grade gantry-based concrete printers. Our machines include:

✔ Heavy-duty gantry frames

Built to withstand real construction environments.

✔ Advanced extrusion and pump systems

Ensuring smooth, consistent material extrusion.

✔ Automated leveling and control software

for high-precision printing.

✔ Fast assembly and user-friendly operation

suited for both beginners and professionals.

✔ Affordable purchase and rental options

so contractors can adopt 3DCP without massive investment.

Whether you’re building a small house or a large-scale housing community, WolfPack 3DCP machines deliver the performance you need.

Which 3DCP Machine Should You Choose?

The best choice depends on your goals:

Choose Gantry Printers if you want:

✔ full-size homes

✔ fast prints

✔ reliability

✔ commercial projects

✔ best ROI

Choose Robotic Arms if you want:

✔ artistic elements

✔ decorative printing

✔ smaller structures

Choose Mobile Systems if you want:

✔ tall structures

✔ flexible reach

For 95% of construction companies, gantry systems (WolfPack 3DCP) are the smartest choice.

Conclusion

Understanding the different types of 3D concrete printing machines is essential for any builder entering the 3DCP industry. Whether you’re printing homes, walls, or architectural designs, each machine offers unique advantages. WolfPack 3DCP proudly delivers the most reliable and construction-ready systems — powerful, precise, and engineered for modern building needs.