3D concrete printing (3DCP) is revolutionizing the construction industry, not just through speed and design flexibility, but also by offering cost savings compared to traditional building methods. WolfPack 3DCP provides advanced 3D concrete printers and materials that make constructing homes faster, stronger, and more cost-effective.

This guide explains all aspects of 3D-printed house costs, including pricing factors, potential savings, and how WolfPack 3DCP helps contractors and developers plan budgets efficiently.

Why Cost Matters in 3DCP

Traditional construction often involves:

- High labor expenses

- Material wastage

- Long construction timelines

- Unforeseen project delays

3D concrete printing minimizes these costs by automating wall construction, reducing manpower, and optimizing material usage. Builders save both time and money while maintaining high structural quality.

Factors Affecting the Cost of 3D Printed Houses

1. House Size and Design Complexity

- Small homes (1–2 bedrooms): Less material, shorter print time, lower cost.

- Large homes or multi-story buildings: More layers, longer print time, higher cost.

- Complex shapes and curves: Slightly higher cost due to intricate printing paths.

WolfPack 3DCP printers excel at handling complex designs efficiently, keeping costs predictable.

2. Material Costs

- Printable concrete is engineered for fast setting and strong layer bonding.

- High-strength mixes may cost more but provide long-term durability.

- Using WolfPack 3DCP certified mixes ensures cost efficiency by reducing waste and rework.

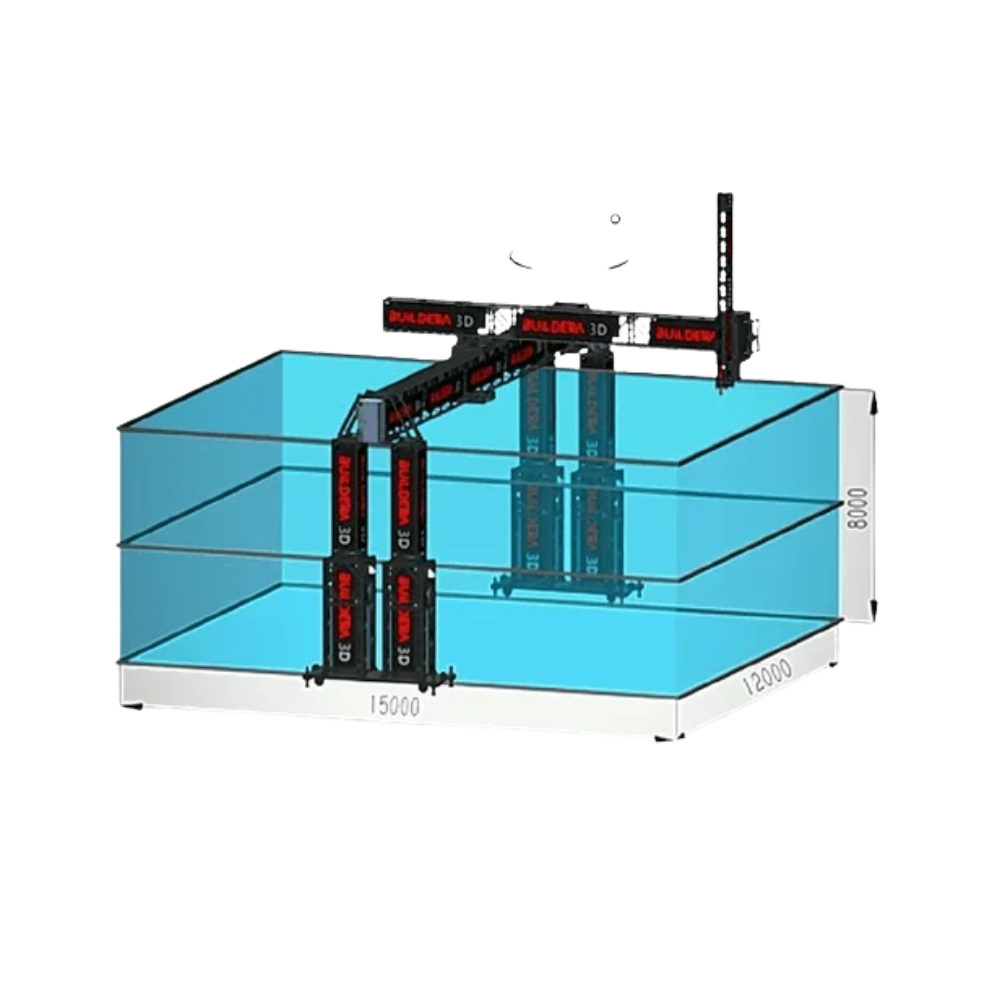

3. Printer Type and Technology

- Gantry printers (WolfPack 3DCP): High precision, large build volume, lower labor costs.

- Robotic arms or mobile systems: Higher cost due to complexity and limited build size.

Gantry printers are most cost-effective for residential construction projects.

4. Labor Costs

- 3DCP requires fewer workers for wall construction.

- Traditional labor for bricklaying and formwork is largely eliminated.

- WolfPack 3DCP provides training for operators to reduce mistakes and downtime, further saving costs.

5. Site Preparation

- Flat, stable foundations are required.

- Utility integration (plumbing, electrical) may add to costs.

- Efficient planning with WolfPack 3DCP ensures minimal delays.

6. Finishing and Utilities

- Roofing, doors, windows, and interior finishes are additional expenses.

- Structural walls are already printed, reducing time and cost compared to traditional methods.

Average Cost Comparison: 3D Printed vs Traditional Houses

| House Type | Traditional Construction Cost | 3D Printed (3DCP) Cost | Savings |

| Small 1-Bedroom | $60,000 | $35,000–$40,000 | 35–40% |

| Medium 2–3 Bedroom | $100,000 | $60,000–$70,000 | 30–40% |

| Large 4+ Bedroom | $150,000 | $90,000–$110,000 | 35–40% |

These numbers vary by region, material quality, and design complexity, but 3DCP consistently lowers overall construction costs.

Why 3DCP Is More Affordable

1. Reduced Labor Costs

With 3D concrete printing, one machine can replace dozens of workers. WolfPack 3DCP printers handle precise wall printing automatically, cutting labor expenses dramatically.

2. Less Material Waste

Traditional methods often over-order concrete and bricks. 3DCP uses exact amounts, reducing waste by 30–50%.

3. Faster Construction Time

Printing walls in days instead of weeks or months reduces indirect costs like site management, rentals, and insurance.

4. Lower Long-Term Maintenance

High-strength printed concrete reduces the risk of cracks, water damage, or structural issues, saving money over time.

Hidden Costs to Consider

- Foundation Preparation: Must be level and stable.

- Utility Installation: Electrical, plumbing, and HVAC still require traditional installation.

- Permitting and Inspection: Local building codes may require compliance checks.

- Finishing Materials: Windows, doors, roofing, and interior finishes are not part of the print.

WolfPack 3DCP helps contractors plan for these costs to avoid surprises.

Rental Options for Cost Efficiency

For developers and small contractors, WolfPack 3DCP offers printer rental options, allowing:

- Test projects without full purchase investment

- Short-term construction projects to reduce upfront costs

- Access to industrial-grade printers and support

This makes entering the 3D-printed housing market accessible for startups and mid-sized builders.

How to Budget for a 3D-Printed House

- Determine the total build area (square feet or meters).

- Select the 3DCP printer type (gantry, robotic arm, hybrid).

- Estimate material requirements (WolfPack 3DCP provides mix calculators).

- Include labor and finishing costs.

- Add site preparation, permits, and inspection fees.

Following this method ensures accurate cost projections and minimizes surprises.

WolfPack 3DCP Advantage

WolfPack 3DCP makes 3D-printed construction affordable and reliable:

- Industrial-grade printers for full-size homes

- Certified concrete mixes for strength and consistency

- Expert support for project planning and budget estimation

- Rental and purchase options for every business size

- Training programs to optimize operator efficiency

Contractors, developers, and real estate companies can confidently adopt 3DCP technology while controlling costs.

Conclusion

The cost of 3D-printed houses is significantly lower than traditional methods, mainly due to reduced labor, minimized waste, and faster construction timelines. WolfPack 3DCP provides advanced printers, certified materials, and full technical support to ensure projects are budget-friendly, high-quality, and code-compliant.

By adopting WolfPack 3DCP technology, builders can save time, reduce costs, and stay ahead in the modern construction market.