3D concrete printing (3DCP) is transforming construction not only through speed and cost efficiency but also by reducing the environmental impact of building projects. WolfPack 3DCP provides advanced printers and sustainable material solutions that make construction greener, more resource-efficient, and eco-friendly.

This article explores the environmental benefits of 3D concrete printing, comparing it to traditional methods and highlighting how WolfPack 3DCP helps developers build sustainably.

Why Environmental Benefits Matter

Traditional construction is resource-intensive:

- High material waste

- Excessive energy consumption

- Large carbon footprint

- Environmental degradation due to quarrying and transport

3DCP addresses these issues by optimizing material use, minimizing emissions, and enabling sustainable building practices.

1. Reduced Material Waste

Traditional Construction Waste

- Bricks, concrete, and mortar are often over-ordered.

- Formwork and scaffolding generate additional waste.

3DCP Advantage

- WolfPack 3DCP printers extrude exact material quantities based on digital models.

- Layer-by-layer construction reduces leftover concrete by 30–50%.

- Less waste means less landfill disposal and lower raw material extraction.

Impact: Significant reduction in environmental footprint and construction costs.

2. Lower Carbon Emissions

Sources of Emissions

- Transportation of bricks, cement, and materials

- Diesel-powered machinery

- On-site energy consumption

3DCP Advantage

- WolfPack 3DCP printers require fewer machines and fewer transport trips.

- Reduced labor and equipment use lowers energy consumption.

- Optimized concrete mixes can include supplementary cementitious materials like fly ash or slag to reduce CO₂ emissions.

Impact: Cleaner construction with a smaller carbon footprint.

3. Energy Efficiency

Traditional Methods

- Long construction periods increase site energy consumption.

- Heating, cooling, and lighting of partially built structures adds to energy use.

3DCP Advantage

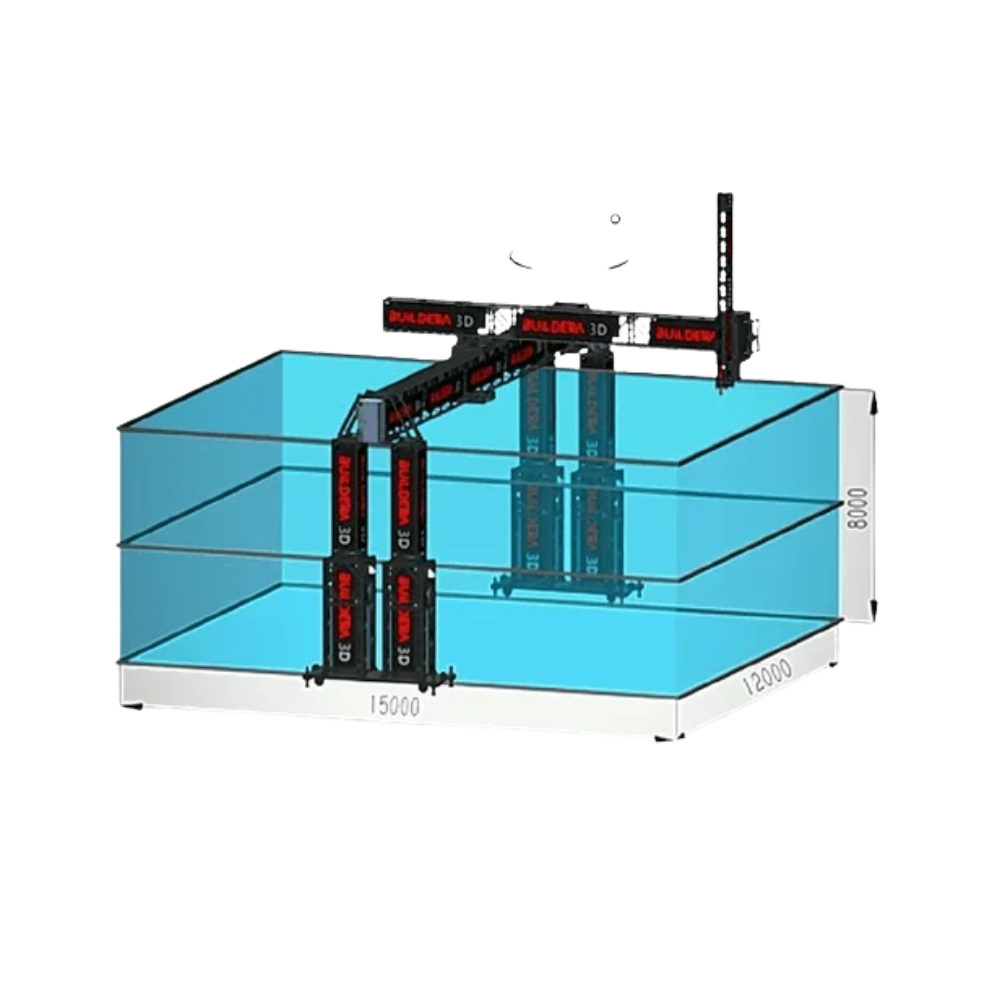

- Faster print times reduce the need for prolonged site energy.

- WolfPack 3DCP’s efficient pump and nozzle systems minimize energy consumption during operation.

Impact: Energy-efficient building process with lower operational costs.

4. Use of Eco-Friendly Materials

- Supplementary Cementitious Materials: Fly ash, slag, and silica fume reduce the need for cement and enhance sustainability.

- Recyclable Aggregates: Some mixes incorporate recycled sand or crushed concrete.

- Low-VOC Admixtures: Reduce chemical emissions during printing.

WolfPack 3DCP offers material guidance and certified eco-friendly mixes for greener construction.

5. Reduced Noise and Dust Pollution

- 3DCP is quieter than traditional construction involving heavy machinery and bricklaying.

- Minimal cutting, drilling, or sanding reduces airborne dust particles.

- WolfPack 3DCP printers operate efficiently on-site, improving both worker safety and environmental quality.

6. Efficient Land Use

- 3DCP allows precise construction of curved and complex structures, maximizing available space.

- Faster construction and smaller footprint reduce disturbance to surrounding ecosystems.

- WolfPack 3DCP supports projects in urban and sensitive areas with minimal environmental disruption.

7. Promoting Green Building Certifications

- 3D-printed structures can help achieve LEED, BREEAM, or EDGE certifications.

- Reduced material waste, energy efficiency, and sustainable concrete mixes contribute points toward certification.

- WolfPack 3DCP assists developers in designing projects that meet green building standards.

8. Long-Term Environmental Benefits

- Durable 3D-printed walls reduce maintenance, repainting, and repairs.

- Energy-efficient homes can incorporate insulation directly into the printed walls.

- Reduced future material replacement and energy use decreases the long-term ecological impact.

Comparison: 3DCP vs Traditional Construction

| Aspect | Traditional Construction | 3DCP (WolfPack 3DCP) |

| Material Waste | High | 30–50% less |

| Carbon Emissions | High | Significantly lower |

| Energy Usage | High | Optimized for efficiency |

| Noise & Dust | High | Minimal |

| Sustainable Materials | Limited | Mixes include fly ash, slag, recycled aggregates |

| Construction Speed | Weeks–Months | Days–Weeks |

WolfPack 3DCP Commitment to Sustainability

- Industrial-Grade Printers: Efficient operation reduces energy use.

- Certified Eco-Friendly Materials: Designed for minimal environmental impact.

- Training & Support: Guides contractors on sustainable printing practices.

- Rental & Purchase Options: Access to green technology without high initial investment.

WolfPack 3DCP enables builders to embrace 3DCP technology while protecting the environment.

Conclusion

3D concrete printing is not just faster and cost-effective; it is environmentally sustainable. By reducing material waste, lowering carbon emissions, optimizing energy use, and using eco-friendly materials, WolfPack 3DCP helps builders construct homes that are strong, durable, and green.

Adopting WolfPack 3DCP technology ensures that construction projects meet modern sustainability standards, support green initiatives, and contribute to a healthier planet.