The construction industry is evolving rapidly, and 3D concrete printing (3DCP) is leading the transformation. WolfPack 3DCP provides advanced 3DCP machines and materials, helping builders achieve faster, stronger, and more efficient construction.

This article compares 3DCP with traditional construction methods, highlighting differences in cost, speed, labor, design, and sustainability.

1. Construction Speed

Traditional Construction

- Walls, floors, and roofs are built manually using bricks, blocks, or formwork.

- Labor-intensive and time-consuming.

- A small house may take 3–6 months or more.

3D Concrete Printing (WolfPack 3DCP)

- Automated layer-by-layer extrusion directly from digital models.

- Walls are printed in days instead of months.

- Faster timelines allow developers to reduce project duration by 50–70%.

Impact: Rapid construction reduces labor, site costs, and time-to-market for housing projects.

2. Labor Requirements

Traditional Construction

- Requires dozens of workers for bricklaying, formwork, plastering, and finishing.

- Labor quality varies based on skill levels.

3DCP (WolfPack 3DCP)

- One operator can manage a 3DCP printer.

- Minimal labor is required for wall printing; finishing work (roof, doors, utilities) still uses traditional labor.

- Consistency and precision are automated, reducing human error.

Impact: Lower labor costs and more predictable results.

3. Material Efficiency

Traditional Construction

- Significant material waste due to over-ordering, cutting, and breakage.

- Concrete, bricks, and mortar often exceed project requirements.

3DCP

- WolfPack 3DCP printers extrude concrete exactly as needed.

- Waste is reduced by 30–50%.

- Optimized mixes ensure high strength with minimal material.

Impact: Cost savings and reduced environmental footprint.

4. Design Flexibility

Traditional Methods

- Limited by formwork shapes and manual construction capabilities.

- Curved walls or complex geometries are expensive and time-consuming.

3DCP

- Digital models allow for curved, organic, or intricate designs.

- Architectural freedom without extra cost.

- WolfPack 3DCP printers can create complex wall geometries with precision.

Impact: Greater creativity, customized homes, and architectural innovation.

5. Structural Strength and Durability

Traditional Construction

- Dependent on craftsmanship; inconsistencies can lead to weak points.

- Manual errors may cause cracking or uneven load distribution.

3DCP

- Layer-by-layer printing with controlled mixes ensures consistent structural strength.

- WolfPack 3DCP materials are tested for compressive strength and durability.

- Reduced human error enhances overall quality.

Impact: Safer, long-lasting structures with predictable performance.

6. Cost Comparison

| Aspect | Traditional Construction | 3DCP (WolfPack 3DCP) |

| Labor | High | Low |

| Materials | Higher waste | Optimized, less waste |

| Construction Time | Weeks–Months | Days–Weeks |

| Cost per m² | $1,000+ | $600–$800 (varies by region) |

| Maintenance | Moderate–High | Lower due to durable layers |

Impact: 3DCP reduces overall construction costs by 30–40% without compromising quality.

7. Environmental Impact

Traditional Construction

- Excessive material waste

- Higher energy consumption

- More CO₂ emissions from machinery and transport

3DCP

- WolfPack 3DCP reduces waste, emissions, and energy consumption.

- Sustainable materials, including fly ash and slag, lower the carbon footprint.

Impact: Eco-friendly, sustainable construction.

8. Safety and Working Conditions

Traditional Construction

- Manual labor carries higher risks of accidents.

- Exposure to heavy materials and equipment increases hazards.

3DCP

- Automation reduces manual labor on-site.

- WolfPack 3DCP printers allow operators to work safely with minimal exposure to risks.

Impact: Safer job sites and reduced occupational hazards.

9. Scalability

Traditional Construction

- Scaling projects requires more workers, materials, and equipment.

- Slow adaptation to large projects.

3DCP

- WolfPack 3DCP printers scale easily for single houses or entire communities.

- Printer rental and purchase options enable flexible adoption.

Impact: Efficient large-scale housing projects and community development.

10. Integration with Modern Technology

- 3DCP works seamlessly with CAD designs, BIM software, and structural simulations.

- Allows real-time monitoring and adjustments during printing.

- Traditional methods rely heavily on manual measurements and inspections.

Impact: Greater accuracy, less rework, and improved project management.

WolfPack 3DCP Advantage

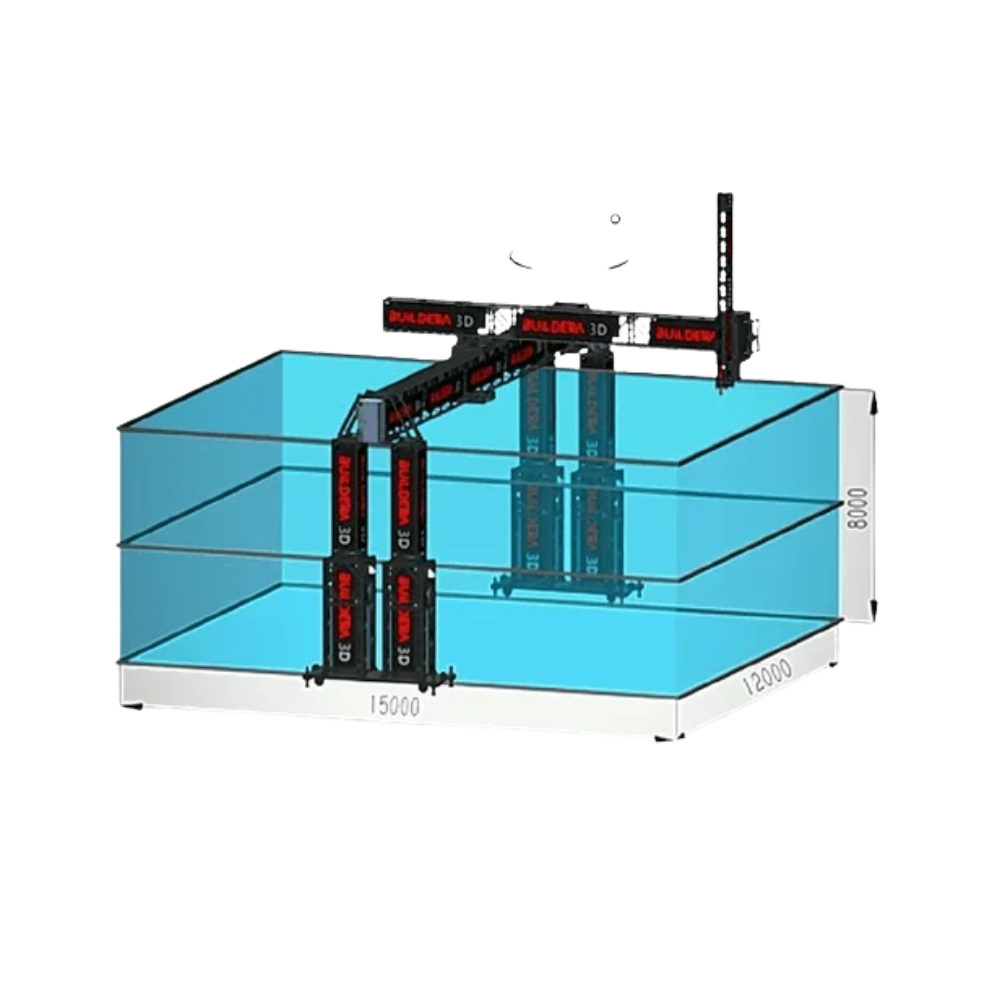

- Industrial-grade gantry printers for full-size homes.

- High-strength, fast-setting concrete mixes.

- Technical support, training, and design assistance.

- Rental options for short-term or pilot projects.

- Environmentally sustainable and cost-effective solutions.

By adopting WolfPack 3DCP, builders enjoy faster construction, lower costs, design flexibility, and eco-friendly practices.

Conclusion

3D concrete printing is superior to traditional construction in nearly every aspect: speed, cost, material efficiency, safety, environmental impact, and design flexibility. WolfPack 3DCP provides advanced printers, materials, and expertise to ensure your 3DCP projects are fast, affordable, durable, and sustainable.

Embracing WolfPack 3DCP technology positions developers and contractors at the forefront of modern construction, ready to meet the challenges of the future.