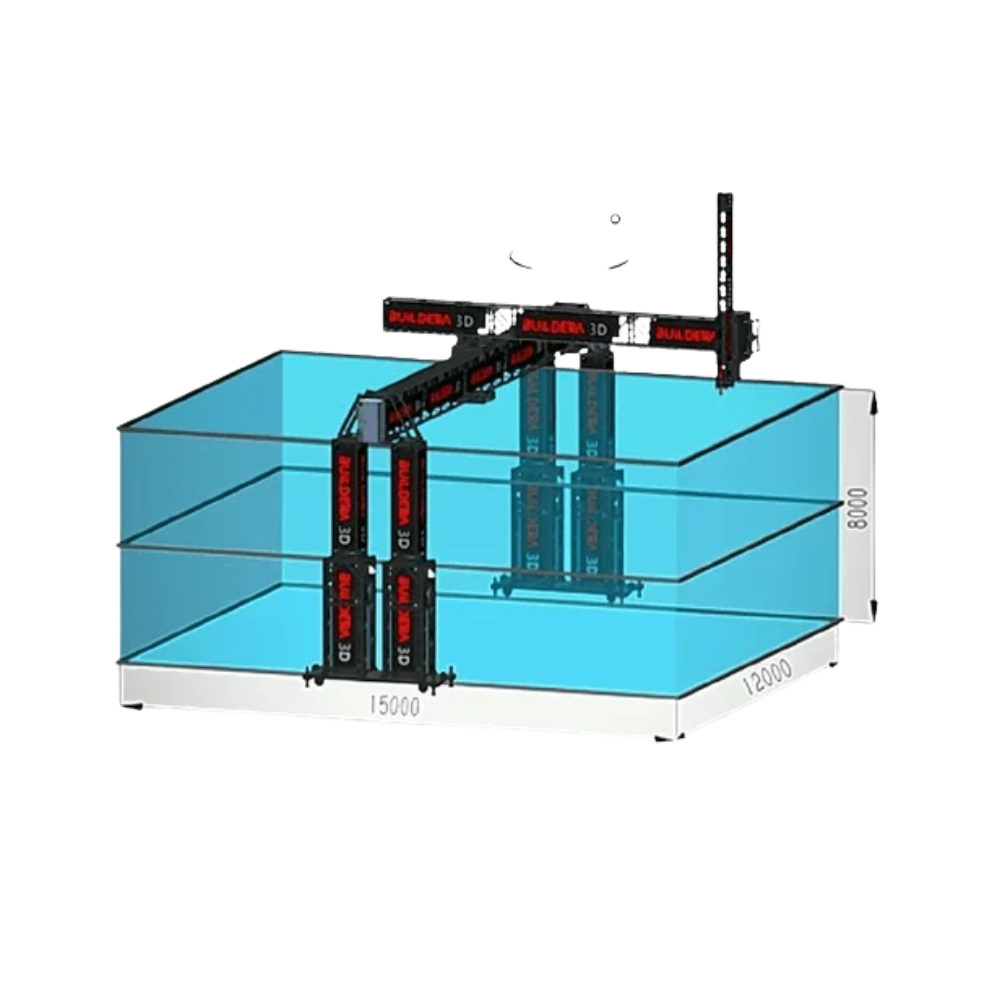

In today’s fast-paced construction industry, efficiency, precision, and cost-effectiveness are no longer optional they’re essential. Traditional mixing and material handling methods often lead to inconsistencies, delays, and higher labor costs. Enter 3D concrete printing (3DCP), a technology that is transforming construction by combining automation with precision engineering.

WolfPack 3DCP, a leading U.S.-based supplier of 3D concrete printing machines, offers innovative solutions for contractors, industrial clients, and construction companies. Their WP 3D Continuous Mixer is at the forefront of this revolution, providing high-performance mortar mixing with exceptional accuracy and reliability.

Why the WP 3D Continuous Mixer is a Game Changer

Consistent, High-Quality Material Preparation

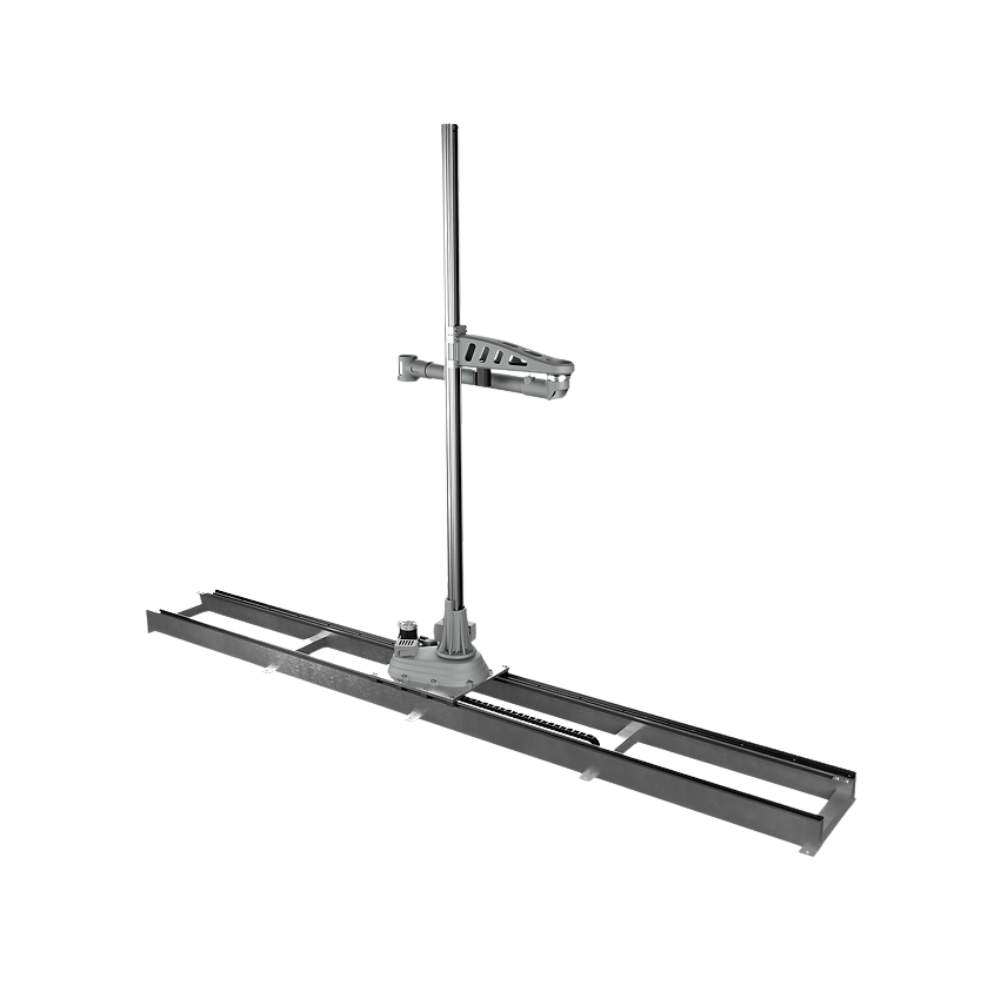

The WP 3D Continuous Mixer is a powerful mortar mixing station designed to provide consistent material preparation for demanding projects. Unlike traditional mixers, it ensures accurate water-to-powder ratios, eliminating guesswork and enhancing the quality of your concrete or mortar. With automated water dosing, every batch is precise, ensuring optimal hydration and reducing waste.

Key Features at a Glance

- Power: 220V, 3kW DC Brushless motor, NEMA 6-50P

- Hopper Capacity: 60L

- Output Flow: 0-500 RPM

- Adjustable Mixing Speed: Dial-controlled for precise material consistency

- Easy Cleaning System: Reduces downtime and maintenance hassles

- Super Sack Compatibility: Efficient bulk material handling

- Seamless Integration: Works perfectly with WP 3D Pump and Sprayer

These features make it ideal for a wide range of applications, including 3D construction printing, plastering, grouting, and masonry projects.

Benefits of Using 3D Concrete Printers in Construction

1. Increased Efficiency and Speed

Using the WP 3D Continuous Mixer reduces manual labor and accelerates project timelines. Automated mixing allows construction teams to maintain a steady workflow, eliminating delays caused by inconsistent material preparation. For example, on a large-scale housing project, contractors can print walls continuously without frequent interruptions for mixing batches.

2. Cost Savings and Reduced Waste

Precise material dosing minimizes overuse and waste, saving money on expensive construction materials. By controlling every aspect of the mix, contractors also avoid costly mistakes from improperly mixed batches, which can lead to structural defects.

3. Enhanced Quality and Durability

The mixer’s precision servo motors and heavy-duty steel construction ensure every batch meets exacting standards. Consistent hydration and mixing improve the strength and longevity of concrete structures, giving clients a durable and reliable end product.

4. Flexibility Across Projects

From residential homes to industrial complexes, the WP 3D Continuous Mixer adapts to various construction needs. Its adjustable mixing speed and super sack compatibility allow contractors to switch between different mortar types and applications effortlessly.

5. Seamless Integration with 3DCP Systems

For contractors using full-scale 3D printing systems, the WP 3D Continuous Mixer integrates directly with WolfPack’s 3D pumps and sprayers, creating a high-efficiency workflow. This integration ensures continuous operation on-site, making it easier to tackle large projects with minimal downtime.

Rental and Purchase Options: Flexibility for Every Contractor

WolfPack 3DCP offers both purchase and rental options, allowing construction companies to choose the solution that best fits their budget and project requirements.

- Purchase: Ideal for companies with ongoing projects who need a reliable, long-term solution. Owning a WP 3D Continuous Mixer ensures consistent access to top-quality material mixing.

- Rental: Perfect for contractors who want to test 3D printing technology or complete short-term projects without committing to a full purchase. WolfPack’s rental program provides access to the latest equipment, fully supported by their team.

Real-World Applications on the Job Site

Consider a construction company tasked with printing custom concrete walls for a commercial building. Using traditional methods, workers would spend hours manually mixing mortar, often facing inconsistencies. With the WP 3D Continuous Mixer, the company can feed precise mixes directly into the 3D printer, producing walls with uniform density and structural integrity in a fraction of the time.

Another scenario is grouting large-scale industrial installations. The mixer’s adjustable flow and automated hydration system allow crews to apply grout continuously, reducing downtime and increasing project throughput.

Why Choose WolfPack 3DCP?

WolfPack 3DCP is a trusted leader in 3D concrete printing equipment, serving construction professionals across the United States. They combine cutting-edge technology, expert support, and flexible purchase or rental options to help contractors innovate and stay competitive.

Contact WolfPack 3DCP today to learn how the WP 3D Continuous Mixer can transform your construction projects.

- Phone: (541) 414-3298

- Email: wolfpack3dcp@gmail.com

- Address: 24852 OR-62, Trail, OR 97541, USA

- Website: wolfpack3dcp.com

Whether purchasing or renting, WolfPack 3DCP ensures you have the tools, support, and technology to succeed. Take the next step in construction innovation and elevate your workflow with 3D concrete printing.