As construction companies across the United States face rising labor costs, tighter timelines, and increasing demand for sustainable building methods, automation has become a strategic necessity, not a luxury. 3D concrete printing (3DCP) is transforming how structures are built, and material delivery systems play a critical role in its success.

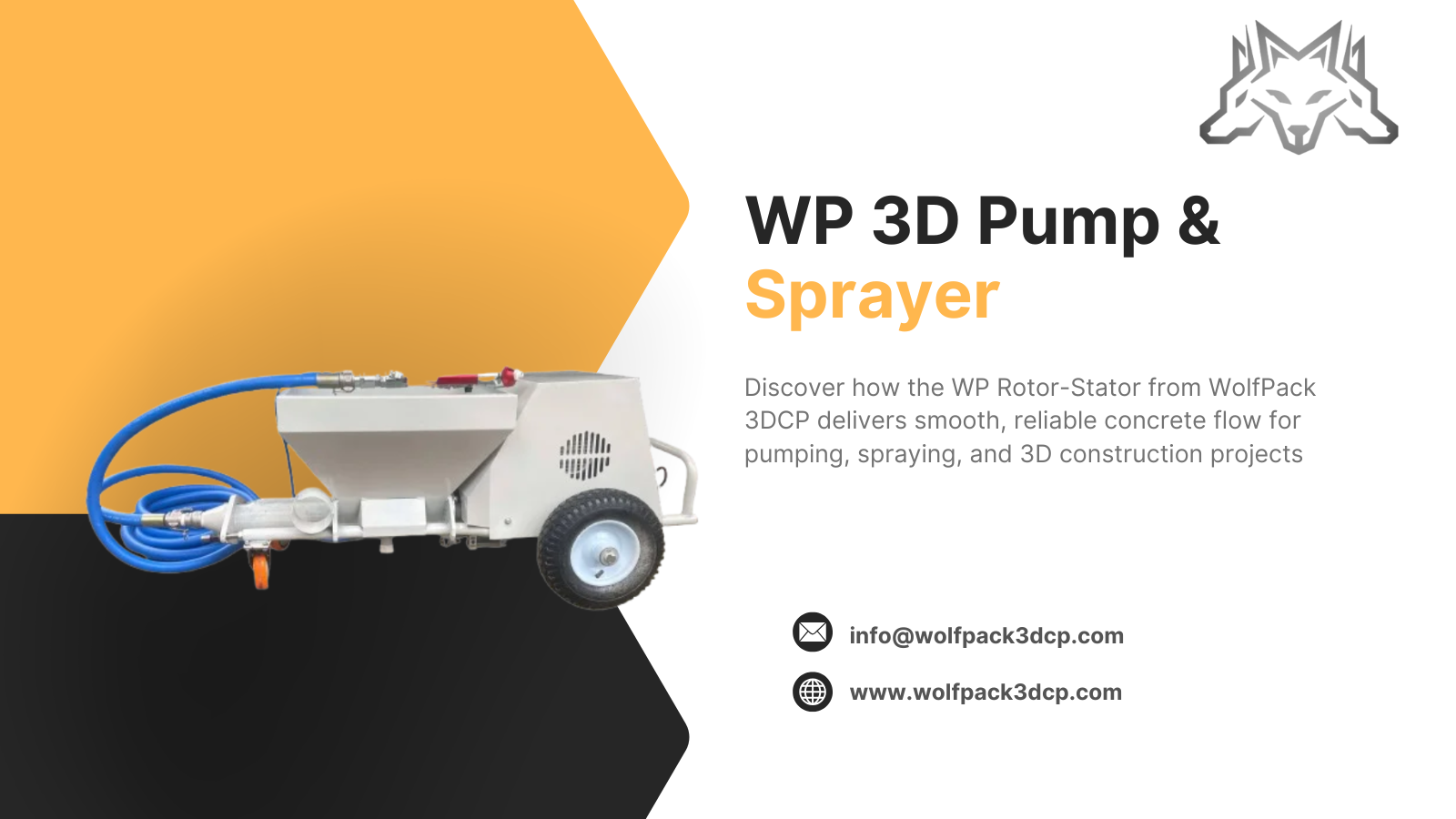

The WP 3D Pump & Sprayer, developed by WolfPack 3DCP, is engineered to support modern construction workflows by delivering consistent, high-pressure mortar application for 3D printing, plastering, and masonry projects. Designed for professional contractors and industrial users, this system helps teams scale faster, reduce waste, and maintain precision on every job site.

Understanding the Role of Material Delivery in 3D Concrete Printing

While 3D concrete printers often receive the spotlight, the pumping and spraying system behind the scenes determines overall performance. Inconsistent material flow can lead to weak layers, downtime, and costly rework.

The WP 3D Pump & Sprayer solves these challenges by ensuring steady, controlled delivery of mortar and concrete mixes, making it an essential component of any 3D construction setup.

Core Technical Capabilities

- Motor Power: 220V, 4kw brushless DC motor

- Maximum Pressure: Up to 40 bar

- Conveying Capacity: 35 liters per minute

- Operating Speed: Adjustable from 0–260 RPM

- Reach Distance: Up to 25 meters vertically or horizontally

- Integrated Protection: Hopper grid prevents clogging

- Complete Spray Kit: Multiple nozzle sizes and cleaning balls included

These features allow contractors to handle demanding workloads while maintaining consistent material quality throughout the project lifecycle.

Key Benefits for Construction Companies and Contractors

1. Faster Project Completion

Time is money in construction. The WP 3D Pump & Sprayer dramatically reduces manual material handling by automating mortar delivery. Whether spraying plaster on exterior walls or feeding material into a 3D printer, crews complete tasks faster and with fewer interruptions.

2. Lower Operating Costs

By reducing labor requirements and minimizing material waste, contractors see immediate cost savings. The pump’s precise flow control ensures only the required amount of material is applied, eliminating overuse and cleanup expenses.

3. Improved Print and Surface Quality

In 3D printed structures, consistent layer bonding is essential. The steady pressure and uniform flow provided by the WP 3D Pump & Sprayer improve print accuracy, resulting in stronger walls and smoother finishes.

4. Scalable for Small and Large Projects

From single-family housing to commercial developments, the system adapts easily. Contractors can use the same equipment across multiple job types, maximizing return on investment.

5. Reduced Worker Fatigue and Safer Sites

Automated spraying minimizes repetitive manual labor and reduces the need for workers to operate on scaffolding for extended periods, creating safer, more efficient job sites.

Real Construction Site Scenarios

Residential 3D Printed Housing

A contractor building affordable housing uses the WP 3D Pump & Sprayer with a continuous mixer to supply material nonstop to a 3D concrete printer. The result: walls completed in days instead of weeks, with consistent structural quality.

Commercial Stucco and Plastering

For a retail development, crews use the sprayer to coat large façade surfaces evenly. Uniform thickness improves aesthetics and durability while reducing finishing time.

Industrial Masonry and Grouting

On infrastructure projects, the controlled spray allows precise mortar placement in joints and cavities, improving structural integrity and extending service life.

These real-world use cases demonstrate how the WP 3D Pump & Sprayer fits seamlessly into both traditional and advanced construction environments.

Seamless Integration with WolfPack 3DCP Systems

The WP 3D Pump & Sprayer is designed to work efficiently with other WolfPack 3DCP products, including the WP 3D Continuous Mixer and 3D concrete printing systems. Together, these machines create a continuous workflow, from mixing to pumping to printing, without unnecessary downtime.

This integrated approach is ideal for contractors aiming to standardize processes and increase productivity across multiple job sites.

Purchase or Rental Options to Match Your Budget

WolfPack 3DCP understands that every construction business operates differently. That’s why they offer flexible purchase and rental options:

- Buy the WP 3D Pump & Sprayer for long-term use and full operational control

- Rent the equipment for short-term projects, pilot programs, or seasonal demand

This flexibility allows contractors to adopt 3D concrete printing technology without excessive upfront costs.

Why Contractors Choose WolfPack 3DCP

WolfPack 3DCP is a trusted U.S.-based provider of professional 3D concrete printing equipment. Contractors choose WolfPack 3DCP because of their:

- Industry-proven machinery built for real job sites

- Focus on performance, durability, and efficiency

- Expert support for equipment selection, setup, and operation

From small construction firms to large industrial clients, WolfPack 3DCP delivers solutions that help businesses stay competitive in a rapidly evolving market.

Contact WolfPack 3DCP Today

If you’re ready to modernize your construction workflow, the WP 3D Pump & Sprayer is the tool that bridges innovation and practicality. Whether you’re interested in purchasing or renting, WolfPack 3DCP can help you choose the right solution for your project.

Business Contact Details:

- Brand Name: WolfPack 3DCP

- Phone: (541) 414 3298

- Address: 24852 OR-62, Trail, OR 97541, USA

- Email: wolfpack3dcp@gmail.com

- Website: https://wolfpack3dcp.com

👉 Contact WolfPack 3DCP today to learn how the WP 3D Pump & Sprayer can reduce costs, speed up builds, and elevate the quality of your construction projects.