Construction technology is evolving, and 3D concrete printing is leading the shift toward automation, precision, and cost-effective building methods. Contractors today face rising labor costs, material waste, and project delays. To stay competitive, many are turning to large-scale 3D construction printers that streamline workflows while improving build quality.

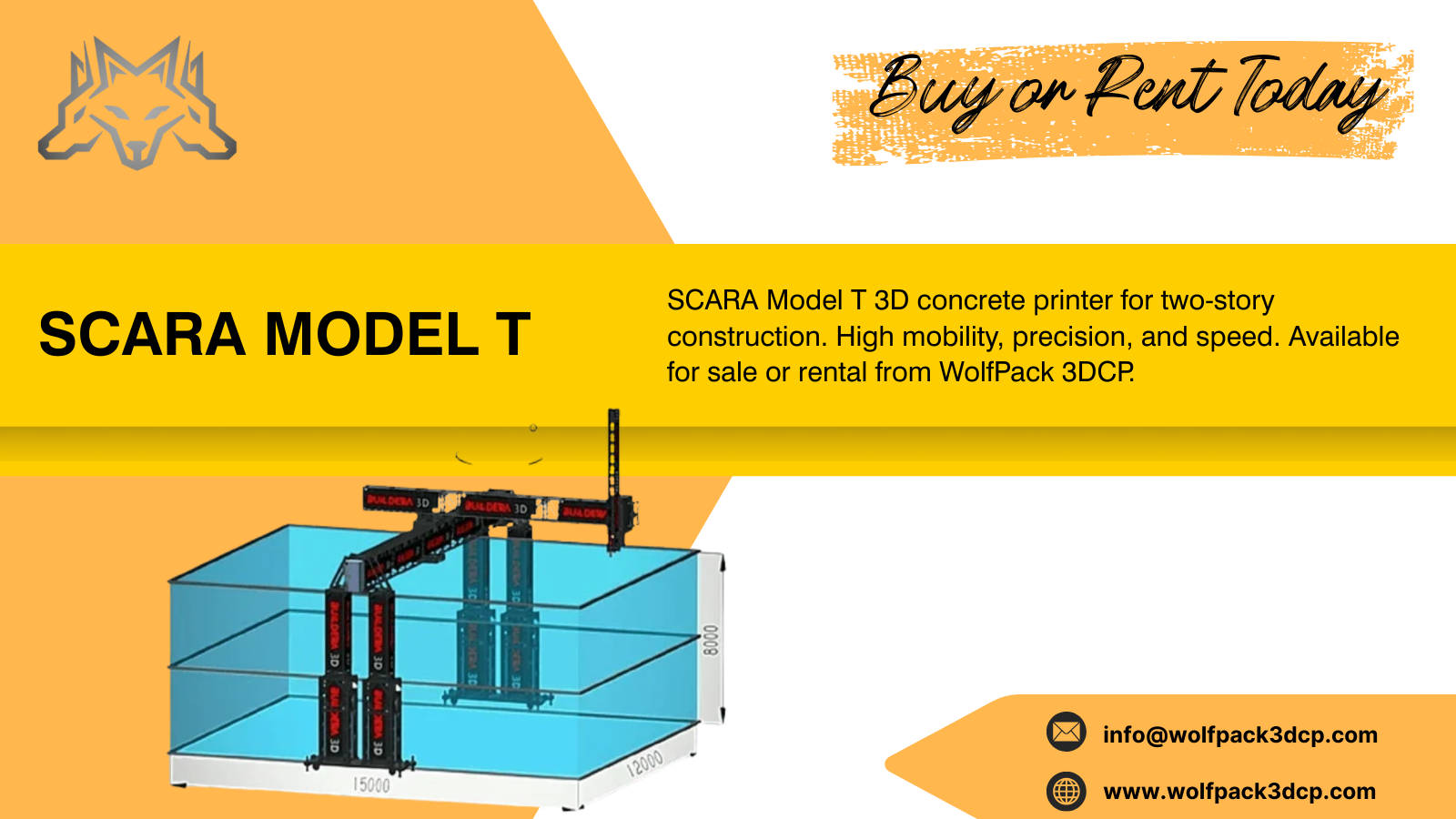

The SCARA Model T, developed by BUILDERA 3D and integrated by WolfPack 3DCP, is a powerful solution designed to bring industrial-grade performance directly to construction sites and prefabrication facilities. With its advanced robotic arm system, exceptional mobility, and ability to print two-story structures, this printer represents a new era in 3D construction technology.

Understanding the SCARA Model T 3D Concrete Printer

The SCARA Model T is a large-format 3D concrete printing machine built on a Selective Compliance Assembly Robot Arm (SCARA) platform. Unlike traditional gantry systems that operate within fixed frames, SCARA robotics provide flexibility, speed, and extended reach.

Engineered through 10+ years of 3D concrete printing research and backed by over 20 years of heavy gantry crane expertise, the system is built to perform reliably in demanding construction environments.

WolfPack 3DCP offers the SCARA Model T through purchase and rental programs, giving companies flexible access to advanced printing technology.

Core Features That Drive Performance

Two-Story Structural Printing

One of the most defining features of the SCARA Model T is its two-story construction capability. With a vertical build height of up to 8 meters, contractors can print full-scale residential homes, commercial structures, and large structural components using one integrated system.

This expands the role of 3D concrete printing from small-scale demonstrations to real-world building projects.

High Mobility for On-Site Deployment

Construction sites require adaptable equipment. The SCARA Model T is compact, foldable, and easy to transport, allowing crews to deploy it quickly across multiple job sites.

This mobility makes it practical for:

- Residential developments

- Commercial construction

- Industrial building projects

Faster setup means projects can move forward without long equipment preparation times.

Wide Reach and Precision Control

The printer features a 15-meter maximum arm reach and 180° arm rotation, enabling broad coverage and efficient material placement. This reduces the need to reposition equipment and supports the creation of complex geometries, curved walls, and custom architectural designs.

Precision layer placement enhances structural consistency while minimizing material waste.

Flexible Printing Parameters

The SCARA Model T adapts to various project requirements with:

- Adjustable nozzle sizes

- Variable pump speeds

- Layer heights from 3–20 mm

These settings allow operators to balance speed, detail, and structural strength depending on project needs.

Built for Tough Construction Environments

Durability is essential in construction equipment. The SCARA Model T uses IP65-rated components, offering protection against dust and moisture. Its rugged design ensures consistent performance in outdoor job-site conditions as well as indoor facilities.

Operator-Friendly System

Despite its industrial power, the SCARA Model T is designed for ease of use. Its intuitive interface and seamless software integration allow operators to control printing parameters efficiently. Maintenance is straightforward, helping minimize downtime.

Technical Specifications

- Print Volume: 12m × 15m × 4m (up to 8m for two-story builds)

- Layer Height: 3–20 mm (adjustable)

- Print Speed: 50–300 mm/s (optimal range: 10–20 cm/s)

- Material Compatibility: Portland Cement Grade 325+ and high-performance mixes

- Power Supply: 380V

- Protection Rating: IP65

Real Construction Use Cases

On-Site Housing Construction

Builders can print structural walls directly on residential sites, cutting labor demands and reducing reliance on traditional formwork. This approach accelerates timelines while maintaining consistent quality.

Modular and Prefabricated Components

In controlled environments, the SCARA Model T produces concrete modules and structural elements for off-site construction. These prefabricated parts can be transported and assembled quickly.

Industrial and Custom Builds

The printer’s reach and precision allow contractors to tackle industrial foundations, specialty structures, and experimental architectural projects that require advanced design flexibility.

Why Partner with WolfPack 3DCP?

WolfPack 3DCP provides industry expertise and flexible options for adopting 3D concrete printing machines. Contractors can choose between purchasing or renting, enabling strategic investment based on project size and demand.

Purchase and Rental Information

The SCARA Model T is available through WolfPack 3DCP via sale or rental.

Accepted payment methods include cash, check, or wire transfer. Credit card payments incur a 3% processing fee.

Contact Details

Brand Name: WolfPack 3DCP

Phone: (541) 414 3298

Address: 24852 OR-62, Trail, OR 97541, USA

Email: wolfpack3dcp@gmail.com

Website: https://wolfpack3dcp.com

Final Call to Action

The SCARA Model T 3D Concrete Printer empowers construction professionals to reduce build times, improve efficiency, and expand design possibilities.

Contact WolfPack 3DCP today to explore purchase or rental options and bring advanced 3D construction printing to your next project.