Modern construction demands speed, precision, and repeatability. As project timelines shrink and labor challenges grow, contractors are turning to 3D concrete printing to stay competitive. But successful 3D printing doesn’t start at the printer — it begins with consistent, high-quality material mixing.

That’s where the WP 3D Continuous Mixer from WolfPack 3DCP makes a measurable difference. Designed for professional construction environments, this advanced mortar mixing station delivers automated, controlled, and uninterrupted material preparation for 3D printing, grouting, plastering, and masonry operations.

For U.S. contractors seeking reliable 3D printing construction machines, this system is a critical link between raw material and structural performance.

The Problem with Traditional Mixing Methods

Manual or batch-based mixing often leads to:

- Inconsistent water-to-material ratios

- Material waste

- Workflow delays

- Higher labor costs

- Variable structural quality

In 3D printing applications, even small inconsistencies in mortar can disrupt layer bonding, surface finish, and structural integrity. Continuous printing requires continuous precision — something traditional mixers simply weren’t built to provide.

Introducing the WP 3D Continuous Mixer

The WP 3D Continuous Mixer is engineered to maintain a steady, precisely controlled flow of mortar, ensuring your 3D printer or pumping system never runs short or receives improperly mixed material.

Core Specifications & Features

- Power System: 220V, 3kW DC brushless motor

- Hopper Capacity: 60 liters

- Output Speed: 0–500 RPM adjustable flow

- Dial-Control Mixing Speed for on-the-fly adjustments

- Automated Water Dosing System

- Super Sack Compatible for bulk materials

- Quick Cleaning Design to reduce downtime

- Heavy-Duty Construction built for job site conditions

- Seamless Integration with WP 3D Pump & Sprayer

This isn’t just a mixer — it’s a productivity tool designed specifically for modern 3D concrete printing workflows.

Key Benefits for Construction Companies

1. Continuous Operation = Faster Builds

Because the system delivers an uninterrupted supply of mortar, crews can keep printers running without frequent pauses. This is especially critical in:

- Housing developments

- Commercial walls and partitions

- Architectural concrete elements

Less downtime means faster project delivery.

2. Precision That Improves Structural Quality

The automated dosing system ensures repeatable material consistency. This results in:

- Better layer bonding

- Smoother extrusion

- Improved compressive strength

- Fewer defects or reprints

For contractors, that means better performance and fewer costly corrections.

3. Reduced Labor Requirements

Manual measuring, water adjustments, and repeated batch mixing take time and manpower. The WP 3D Continuous Mixer automates these processes, allowing crews to focus on placement, printing, and site coordination instead of material prep.

4. Material Cost Savings

Precise mixing reduces overuse of cementitious materials and minimizes wasted batches. Over the course of a large project, this can represent significant cost savings.

5. Job Site Flexibility

With adjustable speeds and compatibility with different mortar types, the mixer adapts easily to:

- Structural 3D printed walls

- Decorative architectural features

- Industrial grouting

- Plaster and repair applications

Real Construction Site Scenarios

Scenario 1: 3D Printed Residential Walls

A contractor printing exterior wall systems needs steady extrusion to maintain wall geometry. The WP 3D Continuous Mixer feeds consistent mortar into the printer, ensuring clean layer stacking and uniform density from start to finish.

Scenario 2: Commercial Interior Structures

During a fast-track office build, crews use 3D printing to form partition walls. Continuous mixing allows non-stop printing, reducing construction time compared to block or formwork methods.

Scenario 3: Industrial Grouting Projects

For large equipment foundations, the mixer supplies uniform grout continuously, improving placement speed and final strength.

Designed for Full System Integration

The WP 3D Continuous Mixer works seamlessly with WolfPack’s broader ecosystem of 3D printing construction machines, including pumps and sprayers. This integrated workflow creates:

Material → Mixing → Pumping → Printing

A streamlined process that supports industrial-level performance.

Purchase or Rental — Built Around Your Needs

WolfPack 3DCP understands that contractors operate under different project demands and budgets.

Purchase Option

Ideal for companies with ongoing 3D printing operations who want a long-term asset that boosts productivity on every job.

Rental Option

Perfect for:

- Pilot programs

- Short-term projects

- Companies exploring 3D concrete printing

Renting allows contractors to adopt advanced technology without large upfront investment.

Why Contractors Trust WolfPack 3DCP

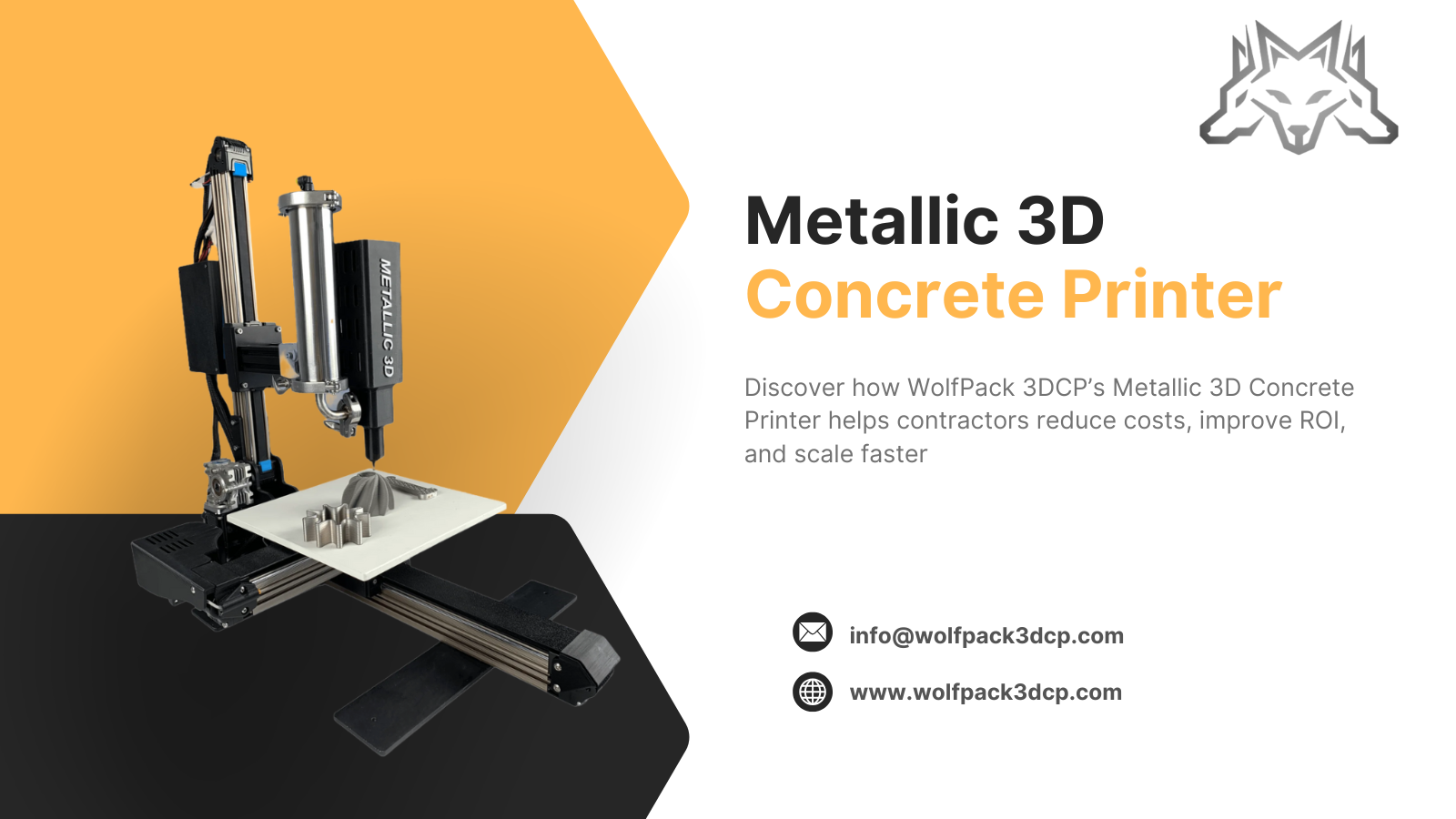

WolfPack 3DCP is a U.S.-based provider specializing in advanced equipment for 3D concrete printing. They support construction professionals with high-performance machines, expert guidance, and flexible acquisition options.

Contact Information:

WolfPack 3DCP

📍 24852 OR-62, Trail, OR 97541, USA

📞 (541) 414 3298

📧 wolfpack3dcp@gmail.com

🌐 wolfpack3dcp.com

Build Smarter with Continuous Mixing Technology

The future of construction belongs to companies that embrace automation, precision, and efficiency. The WP 3D Continuous Mixer helps contractors modernize their workflows, reduce waste, and improve build quality — all while supporting faster project completion.

Ready to upgrade your mixing system?

Contact WolfPack 3DCP today to purchase or rent the WP 3D Continuous Mixer and power your next 3D concrete printing project with confidence.