In today’s construction industry, productivity depends on more than skilled labor — it relies on precision equipment that delivers consistent results under demanding conditions. Whether contractors are spraying mortar, pumping grout, or operating advanced 3D concrete printing equipment, material flow control is critical.

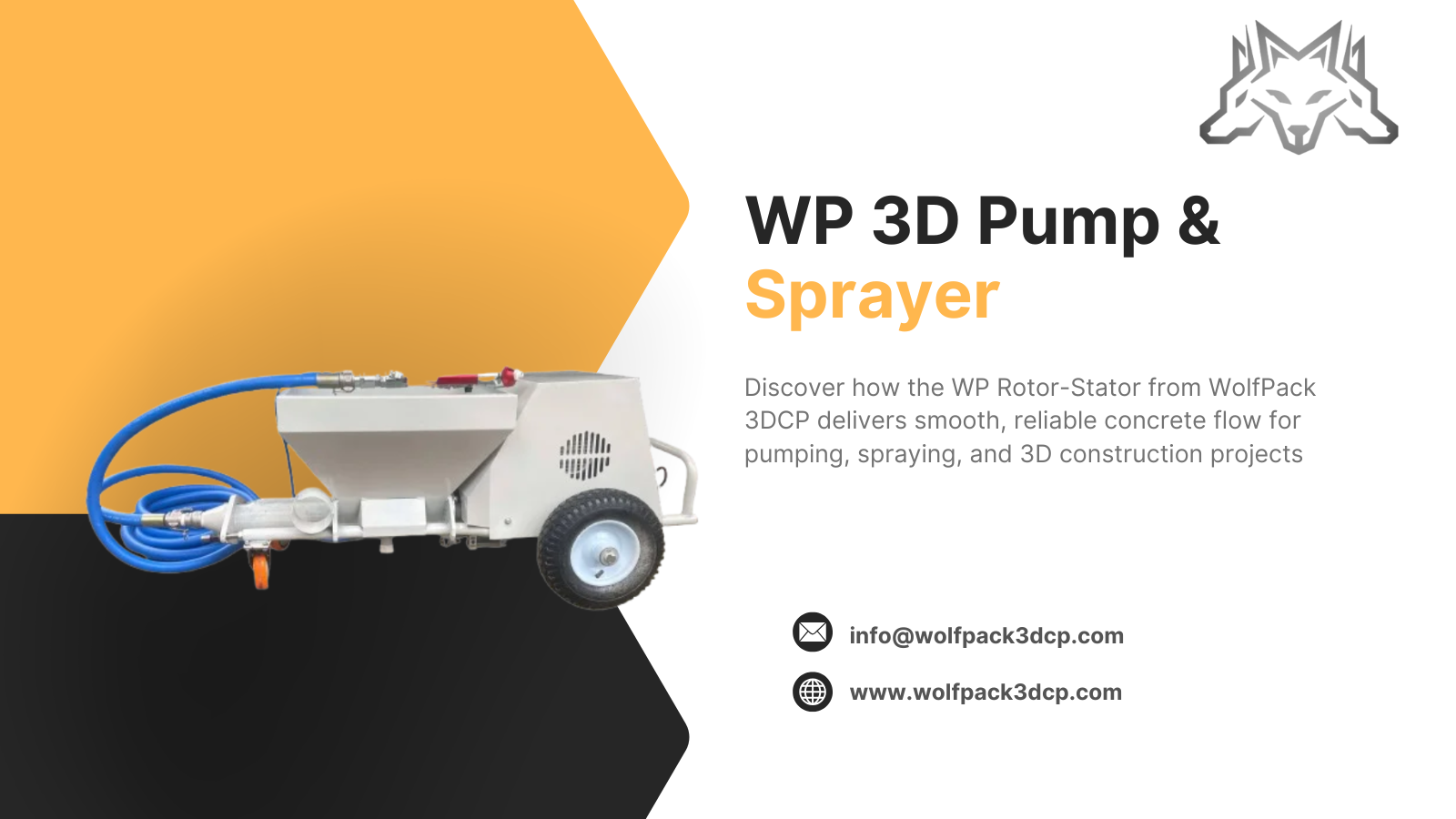

The wp 3D Pump Sprayer from WolfPack 3DCP is built to be the driving force behind smooth, reliable, and efficient material transfer. Designed for high-performance pumping and spraying, this component helps construction professionals reduce downtime, improve finish quality, and maintain consistent output across a range of jobsite applications.

Why Material Flow Control Matters on Today’s Jobsites

Modern construction materials are thicker, more engineered, and often more abrasive than traditional mixes. These materials require specialized concrete pumping and spraying systems that can handle:

- High-viscosity mortars

- Cementitious grouts

- Fiber-reinforced mixes

- Specialty coatings and plasters

Inconsistent flow can lead to:

- Surface defects

- Uneven application

- Equipment strain

- Lost time and wasted material

That’s where a high-quality rotor stator pump for construction becomes essential.

What Makes the WP Rotor-Stator Different?

The WP Rotor-Stator is the core component of a progressive cavity pump for mortar, engineered specifically for demanding construction environments.

Precision-Engineered for Smooth, Pulsation-Free Flow

The system consists of:

- A high-torque steel rotor

- A durable elastomer stator

As the rotor turns, sealed cavities move material forward in a steady, continuous stream. This minimizes pulsation, which is especially important for:

- Consistent spray patterns

- Accurate 3D concrete layer deposition

- Reduced hose stress

Built for Abrasive Jobsite Materials

Construction materials often contain sand, aggregates, and additives that can rapidly wear down standard pump components. The WP Rotor-Stator is optimized for:

- Thick mortars

- Abrasive grouts

- Plaster and render mixes

- Specialty cement-based materials

Its rugged design extends service life, even in tough jobsite conditions.

Reliable Output That Reduces Downtime

Downtime is one of the biggest cost drivers on construction projects. The WP Rotor-Stator supports:

- Stable pressure output

- Even material flow

- Reduced clogging and material surging

This reliability keeps operations running smoothly and crews focused on production rather than repairs.

Three Models for Different Performance Needs

WolfPack 3DCP offers three performance-optimized rotor-stator models to match specific project requirements.

D6-3: Precision and High Pressure

Specs:

- Capacity: 30 L/min @ 400 rpm

- Max Working Pressure: 30 bar

- Max Aggregate Size: 4 mm

Ideal For:

- Detailed applications

- Long hose distances

- High-pressure pumping

This model is perfect when accuracy and pressure stability are top priorities.

D7-2.5: Balanced Performance

Specs:

- Capacity: 50 L/min @ 400 rpm

- Max Working Pressure: 25 bar

- Max Aggregate Size: 4 mm

Ideal For:

- General construction spraying

- Mid-size pumping tasks

- Versatile jobsite use

The D7 provides an excellent balance between flow and pressure.

D8-2: High Flow for Faster Output

Specs:

- Capacity: 66 L/min @ 400 rpm

- Max Working Pressure: 25 bar

- Max Aggregate Size: 4 mm

Ideal For:

- High-volume material transfer

- Faster build rates

- Shorter hose runs

This model supports productivity-focused operations.

Real Jobsite Scenarios

3D Concrete Printing Projects

When contractors use WolfPack 3DCP equipment for 3D concrete printing, consistent extrusion is vital. The WP Rotor-Stator ensures:

- Even layer formation

- Strong interlayer bonding

- Minimal interruptions

This leads to improved structural integrity and faster project completion.

Mortar Spraying and Plastering

In finishing and repair work, surface quality matters. The rotor-stator’s steady flow helps achieve:

- Uniform spray patterns

- Smoother finishes

- Reduced rework

Easy Maintenance and Versatile Compatibility

The WP Rotor-Stator is designed for practical jobsite use:

- Easy installation

- Quick servicing

- Simple replacement

It is built for WP pumps and compatible screw pump systems, offering flexibility for contractors using different setups.

Why Contractors Choose WolfPack 3DCP

WolfPack 3DCP is a U.S.-based provider of advanced 3D concrete printing equipment and pumping components. Contractors choose them for:

- Industrial-grade reliability

- Equipment designed for real-world construction

- Expert support

- Both sales and rental options

Purchase or Rent — Flexible Solutions

Not every project requires permanent ownership. WolfPack 3DCP provides:

- Rotor-stators for purchase

- Rental options alongside 3D concrete printers

This allows companies to scale operations based on project size and budget.

Contact Information

WolfPack 3DCP

📞 Phone: (541) 414 3298

📍 Address: 24852 OR-62, Trail, OR 97541, USA

📧 Email: wolfpack3dcp@gmail.com

🌐 Website: wolfpack3dcp.com

Final Call to Action

If your project demands reliable pumping, smooth spraying, or precise 3D concrete material delivery, the wp 3D Pump Sprayer is built to perform.

Contact WolfPack 3DCP today to purchase or rent the right rotor-stator and equipment setup for your next construction job.