3D concrete printing (3DCP) is revolutionizing construction with faster builds, lower costs, and innovative designs. However, like any emerging technology, it faces several challenges and limitations that builders, developers, and contractors must understand. WolfPack 3DCP provides advanced printers, materials, and expert guidance to overcome these hurdles, enabling safe, reliable, and cost-effective 3DCP projects.

This guide explores the major challenges of 3D concrete printing, including technical, material, regulatory, and operational issues.

1. Material-Related Challenges

a. Printable Concrete Mixes

- Achieving the perfect balance between flowability, strength, and setting time is difficult.

- Incorrect mixes can cause clogging, sagging, or weak structures.

- WolfPack 3DCP provides certified, industrial-grade mixes optimized for layer bonding and durability.

b. Consistency of Materials

- Variations in sand, cement, or admixtures can affect print quality.

- Maintaining consistent material properties on-site is essential for structural integrity.

c. Durability and Shrinkage

- Poorly formulated mixes may shrink or crack over time.

- WolfPack 3DCP mixes include fibers and additives to prevent cracking and improve long-term durability.

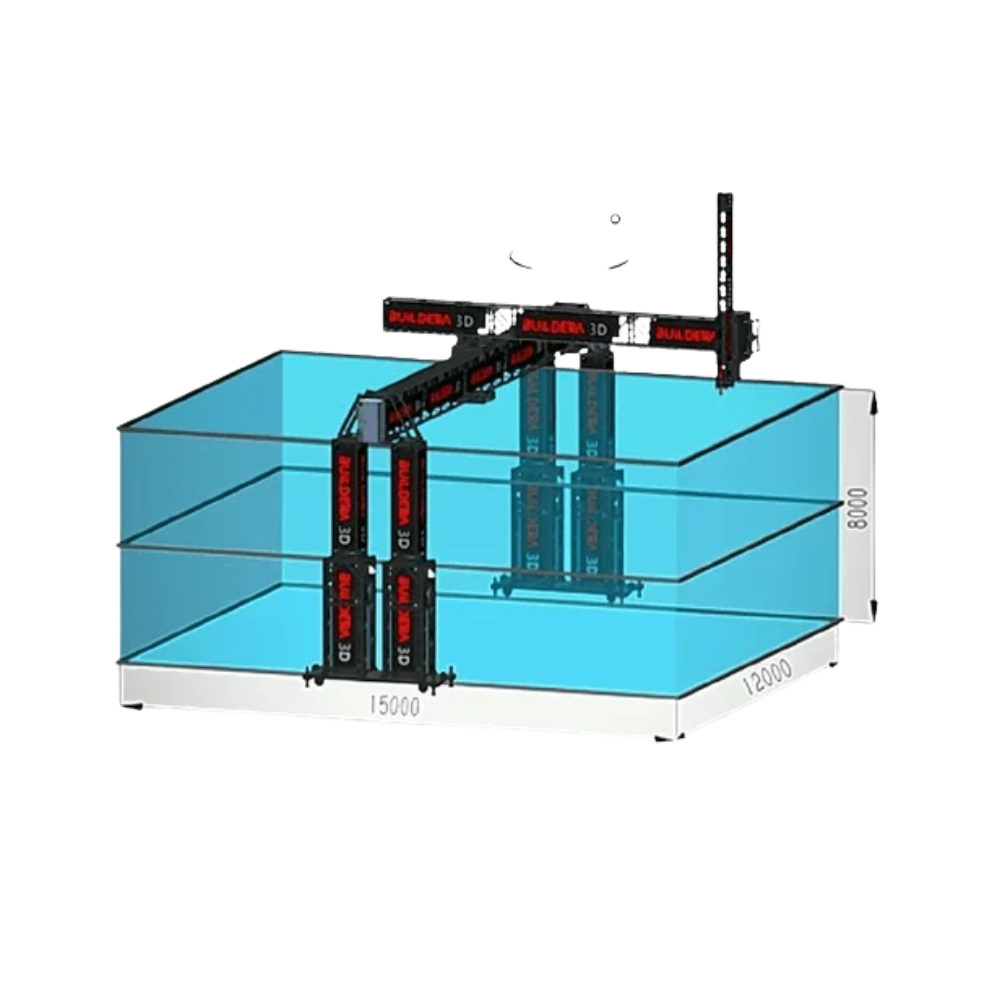

2. Technical Challenges

a. Printer Calibration and Maintenance

- Gantry or robotic-arm printers require precise calibration for accurate layer placement.

- Misaligned printers can cause inaccurate walls or layer misfits.

- WolfPack 3DCP offers training and support to ensure optimal machine performance.

b. Layer Adhesion Issues

- Improper timing between layers can lead to delamination.

- Environmental conditions like temperature and humidity affect bonding.

- WolfPack 3DCP printers and mixes are designed to maintain reliable adhesion under varying conditions.

c. Print Speed vs Structural Stability

- Printing too quickly may cause layers to collapse; printing too slowly affects efficiency.

- Finding the ideal print speed is essential for safety and productivity.

3. Regulatory and Compliance Challenges

- 3DCP is still a relatively new construction method, so building codes may not be standardized.

- Structural, fire, and environmental standards must be met to obtain permits.

- WolfPack 3DCP assists clients in navigating building codes for legal and safe construction.

4. Design and Engineering Challenges

a. Structural Analysis

- Multi-story buildings require advanced engineering calculations.

- Walls must withstand wind loads, seismic forces, and roof weight.

- WolfPack 3DCP works with engineers to ensure printed structures are safe and durable.

b. Complex Geometry

- While 3DCP allows for curved and intricate designs, extreme shapes may require additional support or slower printing.

- Advanced CAD and simulation tools help optimize designs for printability.

5. Site Preparation Challenges

- Flat, level foundations are critical for printing accuracy.

- Uneven terrain or unstable soil can lead to structural issues.

- WolfPack 3DCP provides guidance on site preparation and foundation requirements.

6. Integration with Utilities

- Electrical wiring, plumbing, and HVAC systems still require conventional installation methods.

- Planning conduit channels within printed walls is challenging.

- WolfPack 3DCP offers design support for integrated utilities.

7. Environmental and Weather Challenges

- Extreme temperatures, high humidity, or strong winds can affect printing and curing.

- Rain can wash away layers if not protected.

- WolfPack 3DCP materials are formulated to withstand environmental variability, and protective measures can be implemented on-site.

8. Cost and Investment Challenges

- Initial investment for industrial-grade 3DCP printers can be high.

- Material testing, site preparation, and training add to upfront costs.

- WolfPack 3DCP offers affordable purchase and rental options, reducing entry barriers for startups and contractors.

9. Skilled Workforce and Training

- Operating 3DCP machines requires specialized training in machine operation, material handling, and CAD design.

- Limited availability of trained personnel can slow adoption.

- WolfPack 3DCP provides comprehensive training programs for operators and project managers.

10. Scaling Up Challenges

- Large-scale projects require careful planning of printer logistics, material supply, and sequencing.

- Multi-printer coordination is necessary for building communities or large structures.

- WolfPack 3DCP supports scalable construction solutions for both small homes and large residential projects.

WolfPack 3DCP Solutions for Overcoming Challenges

- Certified Material Mixes: Optimized for flow, strength, and adhesion.

- Industrial-Grade Printers: High precision and reliability for complex projects.

- Technical Support & Training: On-site guidance for printer operation and project planning.

- Regulatory Guidance: Assistance with local and international compliance.

- Rental & Purchase Options: Affordable access to advanced 3DCP technology.

- Design Consultation: CAD and structural optimization for multi-story and complex geometries.

WolfPack 3DCP ensures builders can successfully implement 3DCP technology while minimizing risks and challenges.

Conclusion

While 3D concrete printing offers numerous advantages over traditional construction, it also comes with technical, material, regulatory, and operational challenges. WolfPack 3DCP provides industrial-grade printers, certified materials, expert training, and regulatory guidance to overcome these obstacles.

By leveraging WolfPack 3DCP technology, contractors and developers can build faster, safer, and more cost-effective structures while staying ahead in the modern construction industry.