The construction industry is evolving faster than ever, and 3D Concrete Printing (3DCP) is at the heart of that transformation. From reducing labor costs to enabling complex architectural designs, 3DCP is redefining how we think about building structures.

But innovation alone isn’t enough — it’s about how efficiently and accurately we bring those ideas to life. That’s where WolfPack 3DCP stands as a true leader.

1. The Rise of 3D Concrete Printing

3D Concrete Printing isn’t just a buzzword — it’s a revolution in progress. Using advanced robotics and automated layering, structures that once took weeks can now be built in a matter of days.

- Speed & Precision: Automated layers ensure accuracy at every level.

- Reduced Waste: Only the exact material required is used — no extra cement, no excess cost.

- Design Freedom: Architects can now create complex shapes without worrying about traditional formwork limitations.

2. Sustainability at the Core

With the growing demand for eco-friendly solutions, 3DCP technology offers a path toward sustainable construction:

- Uses less cement and water.

- Minimizes transportation emissions.

- Supports local material usage, reducing environmental footprint.

WolfPack 3DCP focuses on energy-efficient processes and durable materials, ensuring every project aligns with global sustainability goals.

3. Why WolfPack 3DCP Stands Out

WolfPack 3DCP isn’t just offering technology — it’s delivering end-to-end innovation for builders, engineers, and architects.

Key advantages:

✅ Advanced 3DCP machinery designed for accuracy & durability

✅ Easy material handling with Crawling Barrel Mixer and automated systems

✅ Expert team guiding you from setup to printing

✅ Affordable and scalable for small to large-scale projects

WolfPack’s technology is helping construction teams cut project time by up to 60% while maintaining top-notch quality.

4. The Future: Smarter, Faster, Greener

The future of construction lies in automation, digital precision, and sustainability — all of which are built into WolfPack’s DNA.

From residential housing to large-scale infrastructure, 3D concrete printing is no longer the future — it’s the present, and WolfPack is driving that change.

5. Real-World Applications

- Affordable Housing Projects – build faster and cheaper without compromising strength.

- Commercial Spaces – customizable designs for modern architecture.

- Disaster Relief Housing – deploy quickly in crisis zones.

Each WolfPack 3DCP solution is tailored to meet the unique demands of your project.

Conclusion

3D Concrete Printing is not just transforming construction — it’s reshaping the way we build, design, and think.

With WolfPack 3DCP, you’re not just adopting new technology; you’re embracing the future of sustainable, efficient, and innovative construction.

FAQs

Q1. What is 3D Concrete Printing and how does it work?

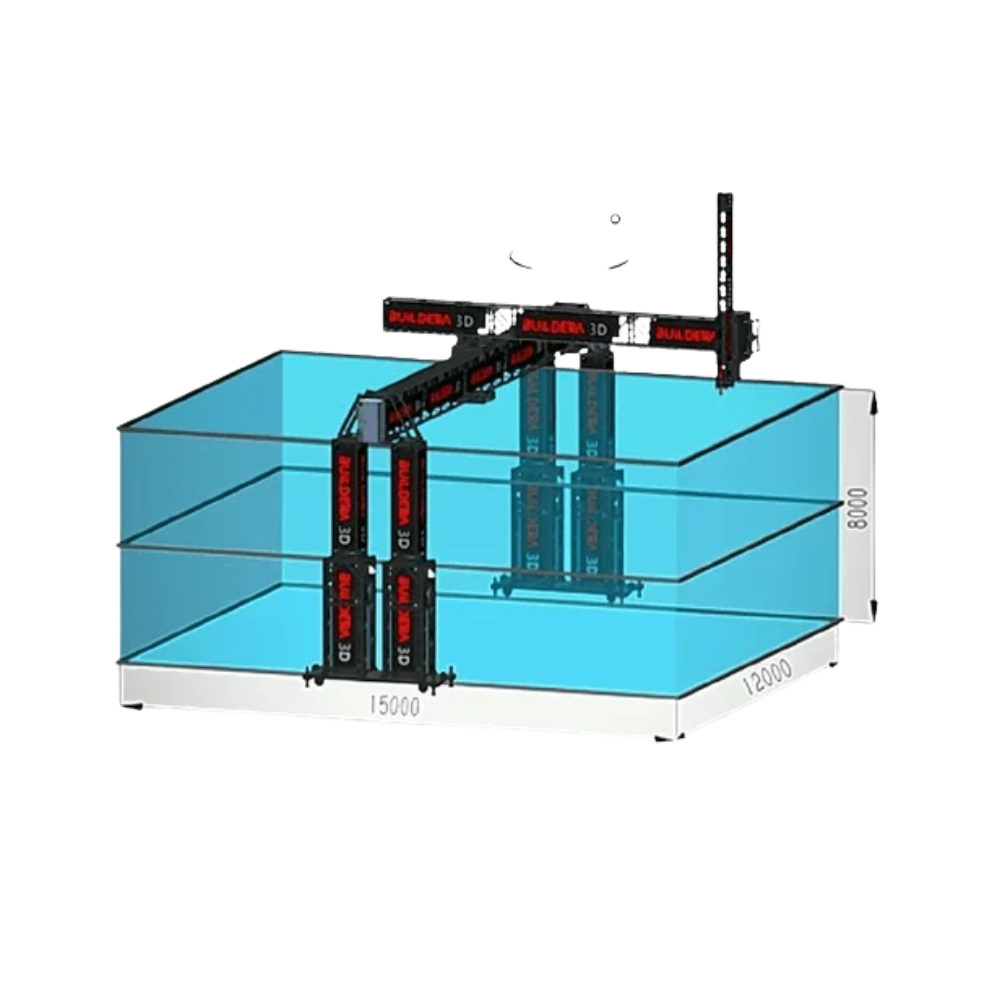

3DCP uses a robotic arm or gantry system to extrude concrete layer by layer, forming walls and structures without traditional molds.

Q2. Is 3DCP cost-effective for large projects?

Yes, WolfPack 3DCP technology minimizes labor costs, material waste, and project delays — ideal for large and complex builds.

Q3. What materials are used in WolfPack’s 3D printers?

WolfPack uses high-performance concrete blends compatible with its Crawling Barrel Mixer, ensuring consistent quality and smooth printing.

Q4. Can 3DCP be used for custom architectural designs?

Absolutely. 3DCP allows for shapes and designs that are nearly impossible with traditional methods — perfect for creative architects.

Q5. How do I get started with WolfPack 3DCP?

Simply visit wolfpack3dcp.com and explore our products or request a demo from our expert team.