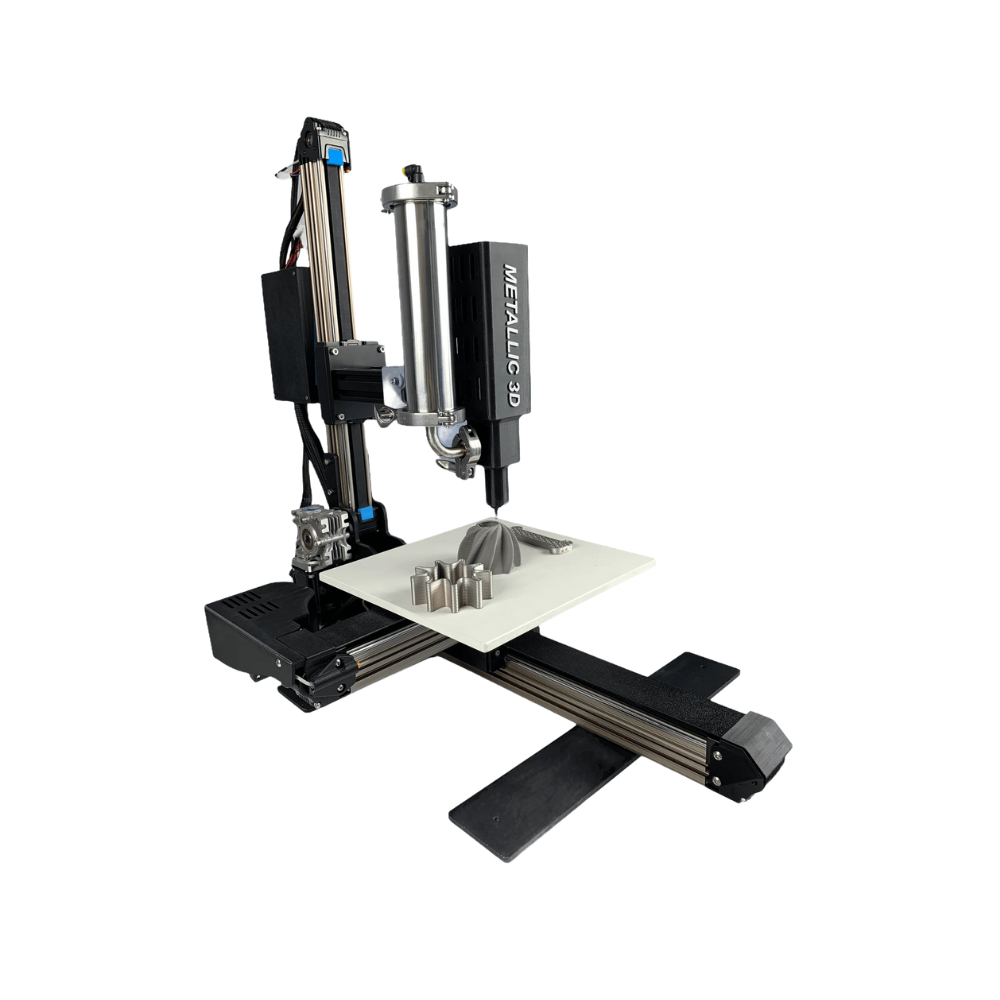

The construction industry is evolving at a rapid pace, driven by innovations that improve efficiency, reduce labor costs, and enhance precision. One of the most transformative technologies leading this revolution is 3D concrete printing. WolfPack 3DCP, a U.S.-based leader in this field, offers high-quality 3D concrete printing machines and accessories, including the WP Rotor Stator, designed to optimize the flow and consistency of concrete for superior printing results.

Whether you are a contractor, construction company, or industrial client, the WP Rotor Stator can dramatically improve your project workflow, whether you choose to purchase or rent the unit.

What is the WP Rotor Stator?

The WP Rotor Stator is a crucial component in 3D concrete printing systems. It ensures smooth, continuous, and precise material flow from the mixing unit to the 3D printer nozzle. By maintaining consistent pressure and reducing blockages, it enhances the reliability and efficiency of your printing operations.

Key Features:

- High-durability rotor and stator materials for long-lasting performance

- Optimized flow for all types of concrete mixes

- Easy integration with WolfPack 3DCP printing systems

- Compact and portable design for onsite use

By reducing downtime and improving print quality, the WP Rotor Stator helps construction teams stay on schedule and maintain higher standards of output.

Benefits of Using a WP Rotor Stator in Construction

Integrating the WP Rotor Stator into your 3D printing workflow can transform how construction projects are executed. Here’s how:

1. Enhanced Printing Precision

The rotor stator ensures that concrete is delivered consistently, allowing for smooth layers and accurate structures. Complex designs, from architectural features to load-bearing walls, can be printed reliably without imperfections.

2. Faster Project Completion

Continuous, uninterrupted flow reduces printing delays, meaning contractors can complete projects faster. For large-scale builds like commercial complexes or residential developments, this can translate to significant cost savings.

3. Reduced Material Waste

Traditional construction methods often result in excess concrete use. With a rotor stator regulating precise flow, material waste is minimized, making projects more sustainable and cost-efficient.

4. Lower Labor Costs

Automated concrete flow reduces the need for manual handling and oversight. Teams can focus on critical tasks, while the 3D printer, equipped with the rotor stator, operates efficiently.

Example Scenario:

Imagine a contractor printing a multi-story concrete wall for a residential development. Without a rotor stator, inconsistent flow could cause weak spots or delays. With the WP Rotor Stator, each layer of concrete is uniform, the printer maintains optimal speed, and the wall is completed in record time with minimal material waste.

Purchase or Rental Options: Flexible Solutions for Every Project

WolfPack 3DCP understands that each construction project has unique requirements. That’s why the WP Rotor Stator is available for both purchase and rental:

- Purchase: Ideal for companies with ongoing projects or multiple printing sites. Owning the rotor stator ensures you have full control over maintenance and usage.

- Rental: Perfect for contractors or industrial clients working on short-term projects. Renting allows you to access top-tier technology without the long-term investment.

Regardless of the option you choose, WolfPack 3DCP provides full technical support and guidance to ensure your machine operates at peak efficiency.

Why Choose WolfPack 3DCP?

WolfPack 3DCP is more than just a supplier – we are a trusted partner in construction innovation. Our team works closely with clients to recommend the best 3D printing solutions, from machines to accessories like the WP Rotor Stator.

Reasons to choose us:

- U.S.-based expertise with industry-leading technology

- Comprehensive support for purchase and rental clients

- Products designed for efficiency, durability, and precision

- Proven track record in enhancing construction workflows

Applications of the WP Rotor Stator in Real Projects

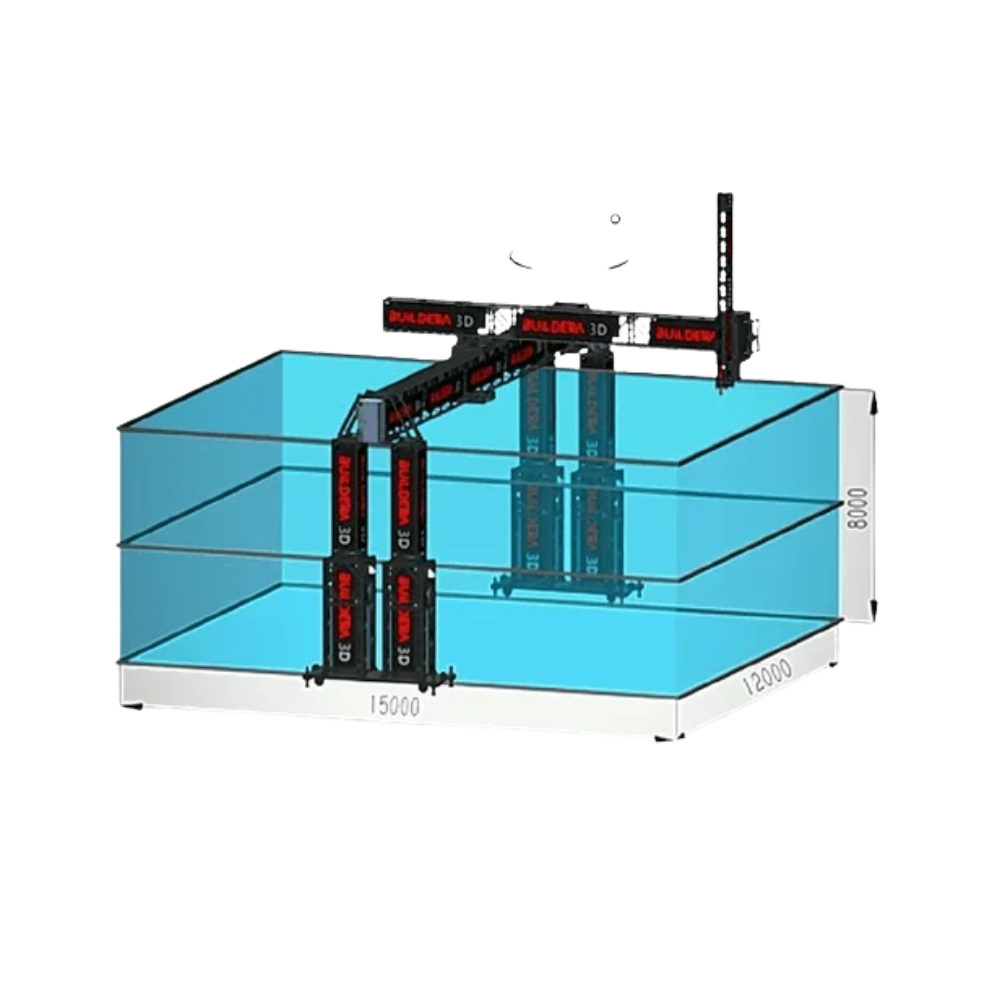

The WP Rotor Stator is versatile and applicable across multiple construction scenarios:

Residential Construction

Efficiently print walls, facades, and custom architectural elements, reducing labor costs and speeding up project timelines.

Commercial Projects

Construct office buildings, warehouses, and retail spaces with precision, ensuring structural integrity and aesthetic quality.

Industrial Sites

Optimize large-scale concrete pouring operations for industrial facilities, bridges, and infrastructural projects, minimizing downtime and improving material flow.

How to Get Started

Upgrading your construction workflow with the WP Rotor Stator is simple. WolfPack 3DCP provides personalized guidance to help clients select the right equipment and determine whether purchase or rental best fits their needs.

Contact WolfPack 3DCP today:

- Phone: (541) 414-3298

- Email: wolfpack3dcp@gmail.com

- Address: 24852 OR-62, Trail, OR 97541, USA

- Website: wolfpack3dcp.com

Our team is ready to answer questions, provide demonstrations, and help you streamline your construction process with the latest 3D concrete printing technology.

Take Your Construction Projects to the Next Level

The WP Rotor Stator is an essential tool for modern 3D concrete printing, offering precision, efficiency, and reliability. Whether you purchase or rent, WolfPack 3DCP ensures that you have the best equipment to complete your projects faster, with less waste and lower labor costs.

Don’t wait to elevate your construction workflow. Contact WolfPack 3DCP today and experience the benefits of advanced 3D concrete printing technology.