In the world of 3D Concrete Printing (3DCP), precision and consistency are everything. A single miscalculation in concrete mix can make or break an entire project. That’s why WolfPack 3DCP introduced the Crawling Barrel Mixer — a next-generation solution built for mobility, power, and unmatched mixing accuracy.

Whether you’re building houses, infrastructure, or large-scale architectural designs, this mixer ensures your 3D printing process runs smoothly from start to finish.

The Challenge with Traditional Concrete Mixers

Traditional concrete mixers were designed for manual construction, not automated 3D printing systems.

They often face issues like:

- Inconsistent mix texture

- Slow operation and frequent downtime

- Difficult handling on uneven terrains

For 3DCP applications, these drawbacks can result in uneven extrusion, clogged nozzles, and project delays.

Meet the WolfPack Crawling Barrel Mixer

The Crawling Barrel Mixer changes the game with smart automation, powerful mobility, and consistent blending technology.

Key Features:

✅ Crawling Functionality – Built to move easily across the job site without manual hauling.

✅ Perfect Mixing Ratio – Delivers uniform, high-quality 3DCP concrete blends every time.

✅ Time-Efficient Operation – Reduces prep time and supports continuous 3D printing.

✅ Durable Construction – Designed for harsh environments and extended industrial use.

✅ Easy Maintenance – Simple cleaning and component access keep downtime minimal.

With WolfPack’s technology, you’re not just mixing concrete — you’re mixing efficiency with innovation.

How It Powers 3D Concrete Printing

3DCP requires a precise, flowable mix that extrudes smoothly through a printer nozzle.

The Crawling Barrel Mixer is engineered to:

- Maintain optimal water-cement ratios for printable consistency.

- Synchronize with WolfPack 3D printers for seamless workflow.

- Support continuous feed systems, ensuring your project never pauses mid-print.

This level of precision guarantees smoother layers, better adhesion, and reduced material waste.

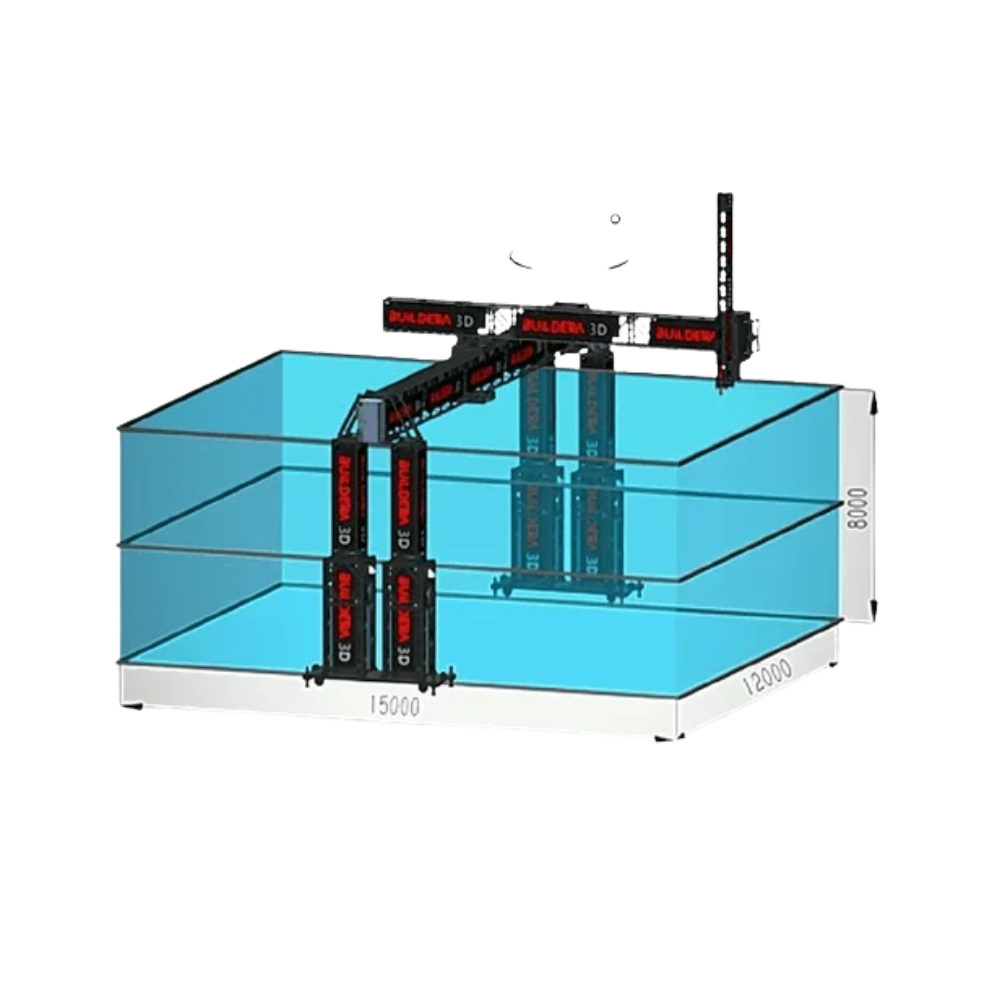

Built for Mobility and Tough Terrain

Unlike static mixers, the Crawling Barrel Mixer is built to move where the work happens.

Its mobile crawler base allows it to travel across the construction site effortlessly — even on uneven or muddy surfaces.

That means less downtime, fewer manual transfers, and faster completion times.

Sustainable and Efficient Mixing

Sustainability is no longer optional — it’s essential.

The Crawling Barrel Mixer minimizes waste through:

- Efficient material usage

- Reduced energy consumption

- Automated control for precise batching

This makes it an ideal choice for companies adopting green construction practices and low-carbon 3D printing methods.

Why Choose WolfPack 3DCP?

WolfPack 3DCP has earned a reputation for engineering excellence and innovation in 3D concrete solutions.

When you choose WolfPack, you get:

✅ Expert guidance on integrating 3DCP systems

✅ Reliable after-sales support

✅ Proven performance in real-world projects

The Crawling Barrel Mixer isn’t just a product — it’s a commitment to efficiency, precision, and progress.

Conclusion

The WolfPack Crawling Barrel Mixer is more than a piece of equipment — it’s the engine of modern construction.

For those who demand speed, accuracy, and reliability, it’s the ultimate partner in 3D concrete printing.

Explore how this innovation can transform your projects and take your construction capabilities to the next level with WolfPack 3DCP.

FAQs

Q1. What makes the Crawling Barrel Mixer different from traditional mixers?

It combines automated mixing with crawler mobility, designed specifically for 3D concrete printing applications.

Q2. Can the Crawling Barrel Mixer integrate with any 3D concrete printer?

Yes, it’s compatible with most 3DCP systems and optimized for WolfPack’s printers.

Q3. How does the mixer improve project efficiency?

It ensures consistent mix quality, faster mobility, and minimal downtime — allowing continuous 3D printing.

Q4. Is it suitable for large-scale projects?

Absolutely. The Crawling Barrel Mixer is built for industrial performance and heavy-duty use.

Q5. Where can I learn more or request a demo?

You can explore specifications and request a demo directly at wolfpack3dcp.com.