In today’s fast-moving world of modern construction, efficiency and precision are everything.

Whether it’s applying bonding agents, curing compounds, or surface coatings, manual spraying just doesn’t cut it anymore.

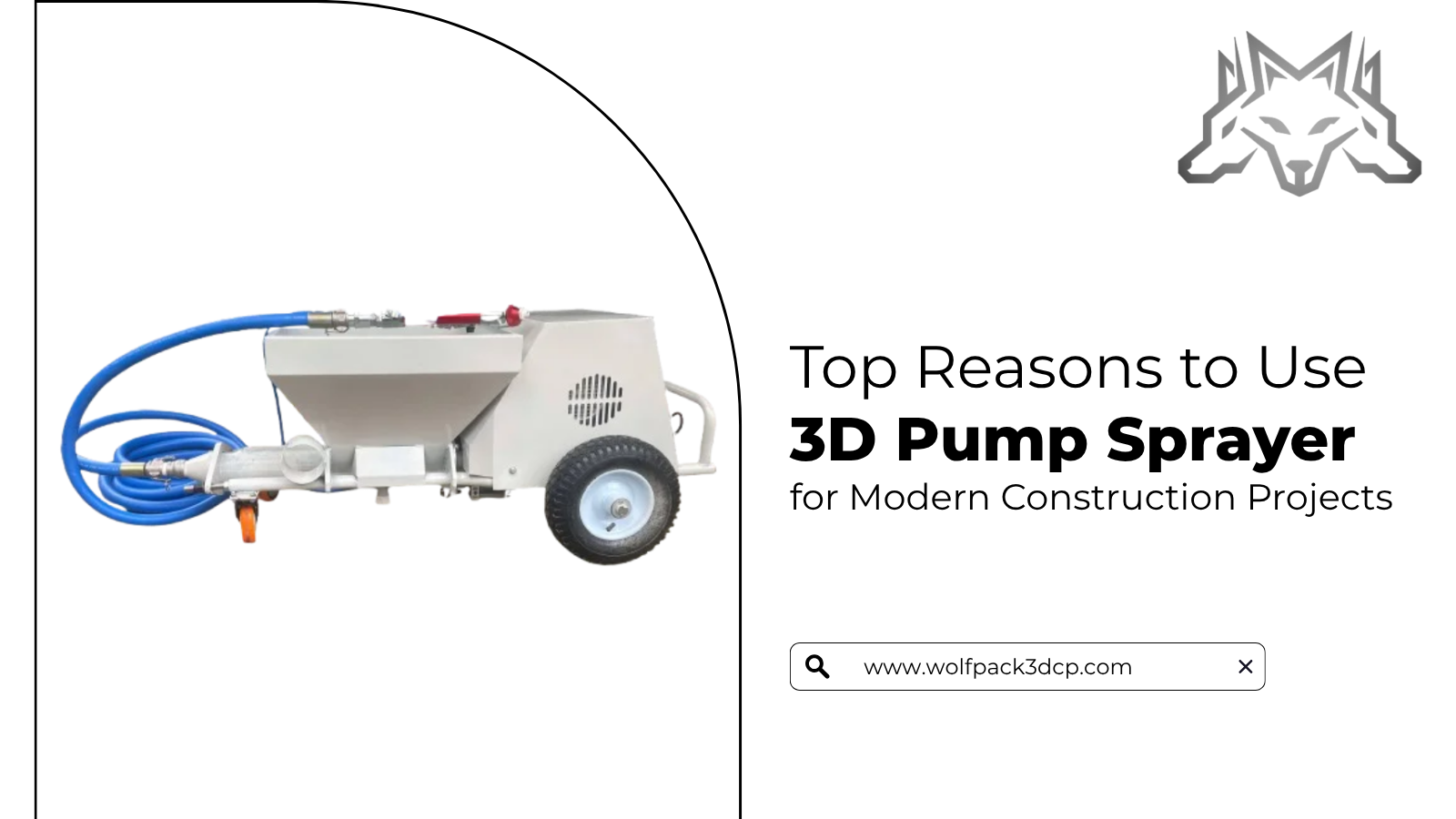

That’s why professionals are turning to the WolfPack WP 3D Pump Sprayer — a next-generation tool designed to make concrete spraying smarter, faster, and cleaner.

This powerful device redefines how surface applications are handled in 3D concrete printing and traditional construction — combining automation, accuracy, and durability in one compact system.

What Is a 3D Pump Sprayer?

A 3D pump sprayer is an advanced pressure-based system that automatically sprays liquid coatings, bonding agents, or curing layers with perfect consistency.

Unlike manual sprayers, which often lead to uneven coverage and waste, the WP 3D Pump Sprayer delivers uniform application every time — saving both material and time.

WolfPack’s model is designed specifically for 3DCP workflows, ensuring perfect coating on printed layers or structural elements before the next layer or process begins.

Why the WP 3D Pump Sprayer Stands Out

WolfPack’s engineering team built this sprayer with industrial performance and user simplicity in mind.

It’s not just a sprayer — it’s a precision-engineered system that integrates perfectly into 3D concrete construction setups.

Key Features

✅ High-Pressure Pumping System – Ensures steady, continuous spray without pulsation.

✅ Adjustable Flow Control – Customize spray rate for different applications and materials.

✅ Anti-Clog Nozzle Design – Handles high-viscosity liquids without blockage.

✅ Durable Stainless Construction – Built to withstand concrete environments.

✅ Portable & Easy to Maintain – Lightweight design for fast movement between work areas.

WolfPack Difference

Where typical sprayers are built for general use, the WP 3D Pump Sprayer is designed for construction-grade precision — tested under real 3D printing conditions for maximum reliability.

Top Reasons to Use a 3D Pump Sprayer in Construction

Unmatched Application Precision

Precision is everything when it comes to 3D concrete printing and finishing.

WolfPack’s 3D Pump Sprayer ensures even coverage of bonding materials and coatings, reducing the risk of weak adhesion or inconsistent curing.

Whether it’s sealing freshly printed walls or applying finishing compounds, the sprayer delivers uniform results every time.

Increased Speed and Productivity

Manual spraying can slow down projects and lead to uneven finishes.

The WP 3D Pump Sprayer automates this process, reducing labor effort and speeding up timelines.

Contractors report up to 50% faster coating times when switching from traditional sprayers.

Reduced Material Waste

Thanks to its smart flow regulation, the WP 3D Pump Sprayer minimizes overspray and dripping —

ensuring that every drop counts.

This not only saves on costly coating materials but also makes your project more environmentally efficient.

Versatility for Multiple Applications

The WolfPack sprayer is compatible with a wide range of materials:

- Curing compounds

- Bonding agents

- Protective coatings

- Pigmented layers

- Finishing sealers

Its modular nozzle system allows you to switch easily between fine mist and heavy coat applications.

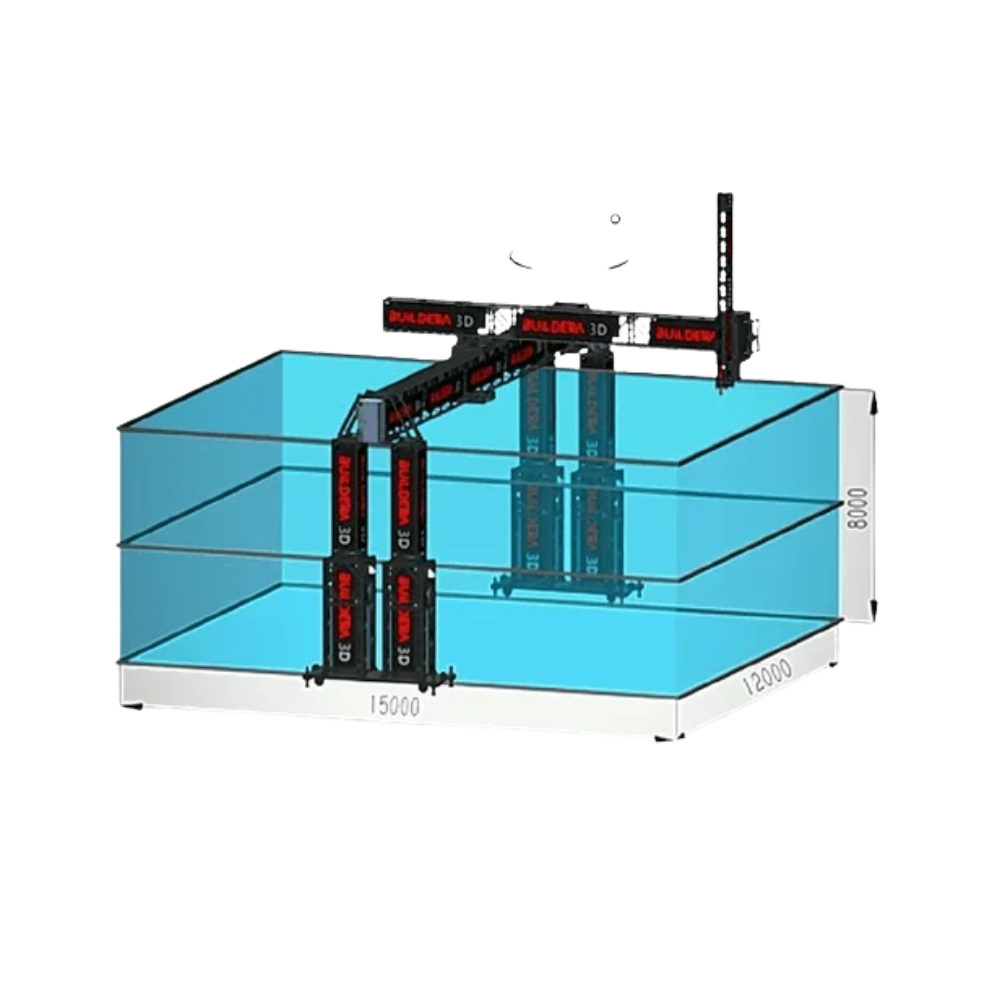

Perfect Fit for 3D Concrete Printing

In 3DCP environments, precision and timing are critical.

The 3D Pump Sprayer integrates seamlessly into the WolfPack ecosystem, supporting other machines like the Material Feed System and 3D Concrete Printer.

It ensures smooth transitions between layers — improving bonding strength and final surface quality.

Enhanced Worker Safety and Ease of Use

With its ergonomic design and automated pressure control, operators can work for longer periods without fatigue.

No more manual pumping, no constant refilling — just plug, spray, and go.

This makes it a worker-friendly and OSHA-safe tool for construction professionals.

How It Works

- Load your coating or bonding material into the sprayer.

- Adjust pressure and flow using the control panel.

- Aim the nozzle toward the surface or printed layer.

- The pump maintains steady pressure, ensuring uniform spray distribution.

The result? Smooth, controlled, and efficient application — whether you’re building a house, a wall, or a structural prototype.

Sustainability and Cost Efficiency

The WP 3D Pump Sprayer aligns perfectly with WolfPack’s green construction mission.

By optimizing material use and eliminating waste, it reduces:

- Material overuse by up to 40%

- CO₂ emissions related to excess product disposal

Fewer resources, lower costs, and a cleaner job site — it’s sustainability made simple.

Conclusion: Small Tool, Big Impact

The WolfPack WP 3D Pump Sprayer is proof that even small innovations can make a big difference in construction efficiency.

By delivering precision, speed, and sustainability, it’s become an essential part of modern 3D printing and building projects.

If your goal is to build smarter, faster, and cleaner, the WP 3D Pump Sprayer is your ultimate ally.

Explore the full product specs at wolfpack3dcp.com

FAQs

Q1. What materials can the 3D Pump Sprayer handle?

It’s compatible with curing compounds, sealers, bonding agents, and similar concrete coatings.

Q2. Can it be used outside of 3D printing projects?

Yes. It’s also ideal for general construction, floor coating, and surface protection applications.

Q3. How does it save material?

The pump uses controlled pressure and flow to avoid overspray and waste.

Q4. Is it portable?

Yes, the lightweight frame and handles make it easy to move between work zones.

Q5. How does it integrate with other WolfPack machines?

It’s designed to synchronize with 3D printing workflows, complementing systems like the Material Feed System and Concrete Printer for full automation.