As the construction industry shifts toward automation, digital design, and sustainability, the demand for large-format 3D concrete printing systems has never been higher. The Scara Model T is WolfPack 3DCP’s answer to this demand — a machine built for scale, precision, mobility and real-world applications.

If you’re serious about printing full walls, multi-story structures, and prefab modules — this is your machine.

1. What Sets the Scara Model T Apart

While many 3D concrete printers target small builds or prototyping, the Scara Model T is engineered for industrial-scale, job-site ready printing. Key differentiators include:

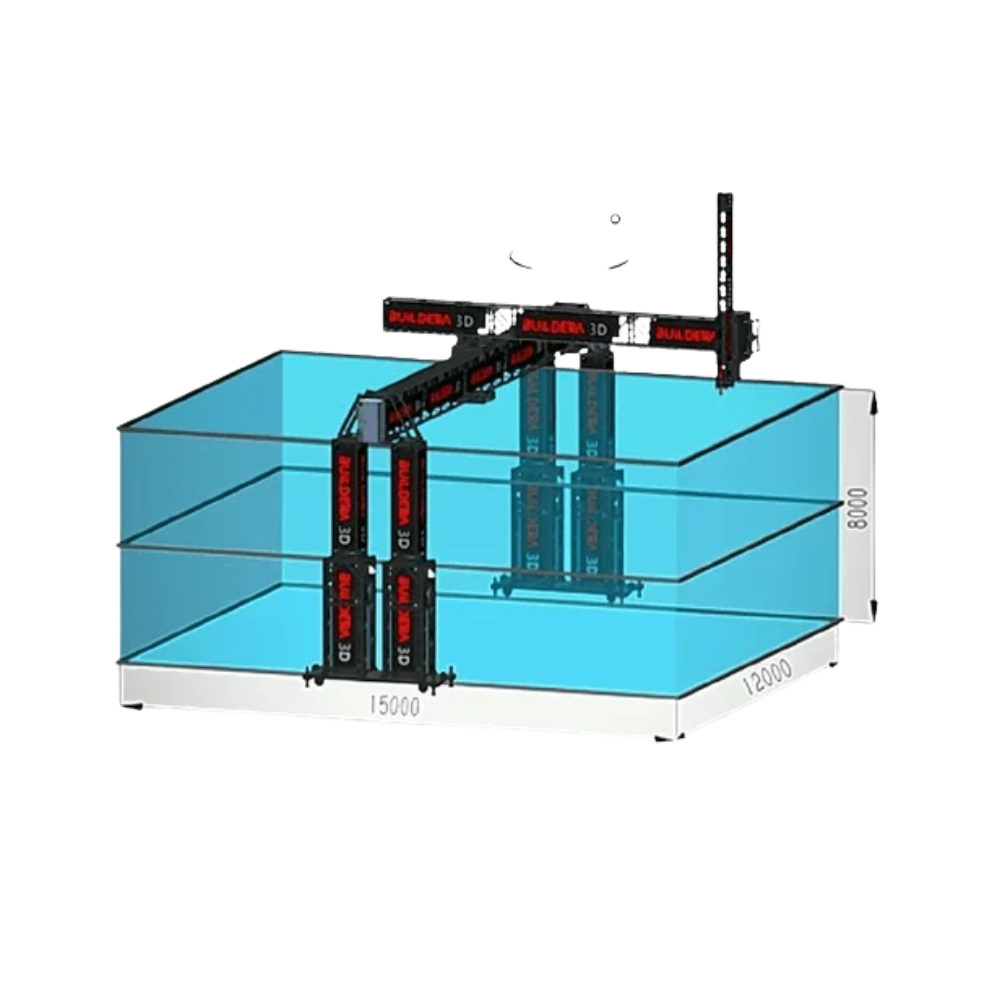

- 12 m width coverage.

- 15 m arm reach and 180° arm articulation.

- Two-story (up to ~8 m height) printing capability.

- Speed range of 50-300 mm/s enabling high throughput.

- Foldable, mobile setup for on-site or prefab facility deployment.

2. Top Reasons to Choose the Scara Model T

2.1 Massive Build Volume for Large Projects

With a 12 m width and 15 m reach, you can handle structures that previously required multiple machines or traditional methods. Whether it’s a two-story house, commercial façade, or modular component — the scale is no longer a limiting factor.

2.2 Speed without Compromise

Achieving print speeds up to 300 mm/s means you get a faster build cycle — while still maintaining layer accuracy and structural integrity. WolfPack’s engineering ensures that speed doesn’t sacrifice precision.

2.3 Precision Layering & Material Control

When you’re printing large volumes, uniform material deposition and layer control are critical. The Scara Model T uses advanced motion control, high-reach robotic arm articulation and is designed to integrate with high-performance mixes for optimal results.

2.4 Mobility Meets Job-Site Flexibility

Unlike large gantry systems that are fixed, the Scara Model T is designed to move — foldable design and rapid deployment make it ideal for multiple sites or factory settings. This flexibility reduces setup time and increases job-site versatility.

2.5 Two-Story & Prefab Ready

Being able to print two-story structures means you’re ready for real residential projects, commercial modules or prefab lines. The machine isn’t just built for demonstration — it’s built for real-world construction.

2.6 Future-Proofing Construction

With automation, digital workflows and high performance built in, the Scara Model T positions your operation for the next wave of construction innovation. Whether you’re scaling, automating or diversifying, this machine supports your growth.

3. How It Works: Workflow Overview

- Site layout prepared, machine deployed.

- The Scara Model T receives the digital model of the structure.

- Arm moves according to programmed path, extruding concrete layers with consistent feed, height and speed.

- Concurrent mixing and feed systems supply material reliably to the print head.

- Finished structure ready for curing, finishing or modular integration.

Each step is optimized for large scale, minimal downtime and high precision.

4. Use-Cases & Applications

- Residential Housing – build full two-story homes faster and with less labour.

- Prefab Modules – print walls or modules in factory settings for easy transport.

- Commercial Buildings & Infrastructures – print large panels, structural elements, façades.

- Design-Driven Projects – curved surfaces, bespoke architecture, large scale installations.

The Scara Model T adapts to continents of use — from urban builds to remote locations.

5. Why WolfPack 3DCP?

WolfPack brings decades of experience in 3D concrete printing, automation and construction engineering. When you invest in the Scara Model T, you’re not just buying a machine — you’re joining a system.

- End-to-end integration with WolfPack’s mixers, pumps and feed systems.

- Global support, installation and training.

- Proven in real-world sites, not just labs.

- A future-forward partner in building innovation.

Conclusion

The Scara Model T is more than a large-format printer — it’s a transformative tool for modern construction. If your aim is to scale, innovate, and lead in 3D concrete printing, this machine is the foundation of that journey.

👉 Discover more on the WolfPack website and elevate your construction capabilities today.

🔗 Explore: https://wolfpack3dcp.com/

FAQs

Q1. What is the maximum print height of the Scara Model T?

It supports up to approximately 8 meters (two-story) build height in standard configuration.

Q2. What material speeds can it handle?

Print speed ranges from 50-300 mm/s depending on configuration and mix.

Q3. Is it mobile or fixed installation?

It is designed for mobility — foldable and rapid deployment on-site or in prefab facilities.

Q4. What build area does it cover?

The machine covers a width of 12 meters and a reach of 15 meters with 180° arm articulation.

Q5. Can it be integrated with other WolfPack systems?

Yes. It works within WolfPack’s ecosystem of mixers, feed systems and material supply to create seamless 3DCP workflows.