If you’re an artist, educator, maker or small-studio operator looking to take advantage of 3D printing into the world of ceramics and clay, then a specialised machine like a clay 3D printer is exactly what you need. In this post you’ll learn what a clay 3D printer is, why it matters, and get an in-depth look at one of the hot models in the US market: the Wolfpack 3DCP Clay 3D Printer.

What is a Clay 3D Printer?

Unlike typical plastic filament or resin 3D printers, a clay 3D printer uses ceramic or clay materials as its medium. That means:

- Printing with real clay (not just plastic made to look like clay) → you get the aesthetic and textural benefits of ceramics.

- Applications extend into pottery, sculpture, architecture prototyping, makerspaces and education.

- It bridges additive manufacturing technology with traditional ceramic techniques.

Why Clay 3D Printing Matters

- Creative freedom: With clay printing you can build shapes and textures that would be extremely hard manually or by traditional methods.

- Studio & educational friendly: A desktop-sized machine means makerspaces, classrooms, hobbyists can adopt this tech.

- Material authenticity: Working with actual clay means you retain the look, feel and firing potential of ceramic art.

- Growing market: As 3D printing evolves, the ceramic/clay niche is becoming more accessible and less industrial-only.

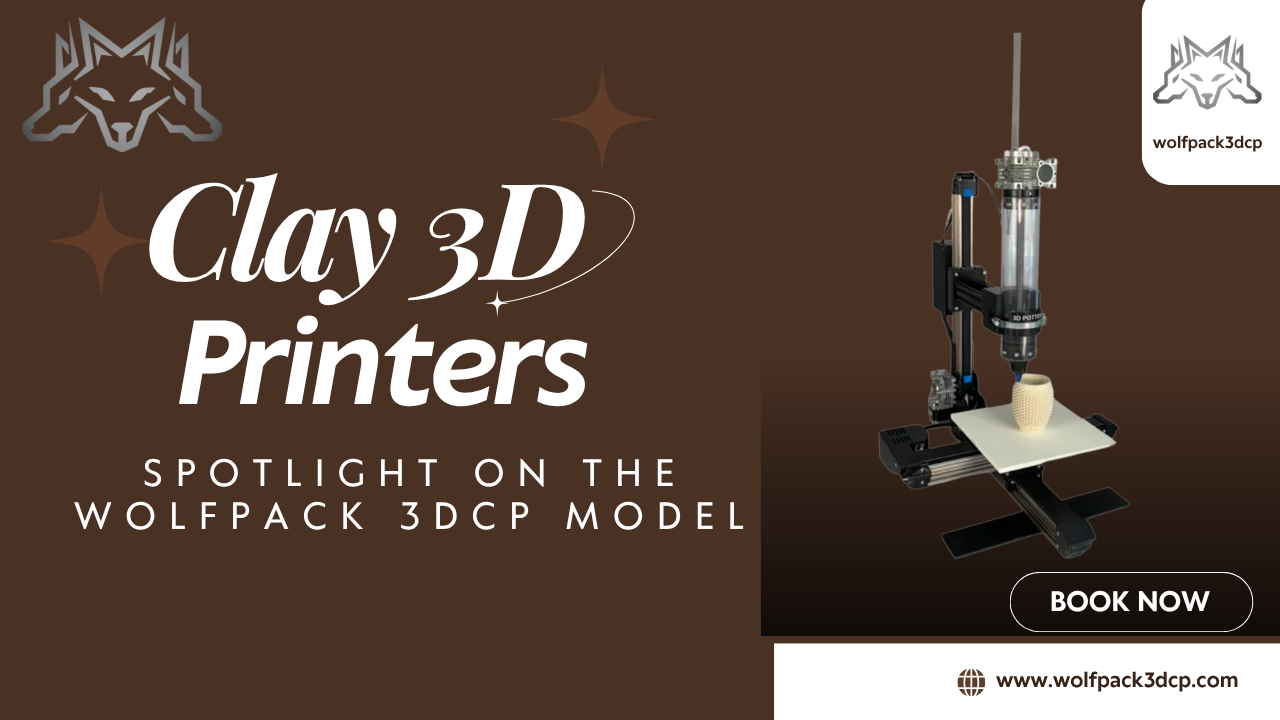

Meet the Wolfpack 3DCP Clay 3D Printer

Here is a breakdown of the key features of the Wolfpack 3DCP model based on the manufacturer/seller specs.

Key Features & Benefits

- Direct Clay Extrusion (No Slip Required) – Print with real clay rather than diluted slip or heavily modified mixtures. That preserves material authenticity.

- Compact & Durable Design – Designed with an anodized aluminum rail system and high-quality components, yet sized to fit on a standard desktop/workbench.

- WiFi-Enabled Control – Built-in web interface means you can upload and manage print files wirelessly without extra drivers/software.

- Versatile Nozzles – Comes with several interchangeable nozzles (3 mm, 4 mm, 5 mm, 6 mm) for different flow rates/detail levels.

Technical Specifications (Highlights)

- Build Volume: 10” x 10” x 12” (X/Y/Z)

- Recommended Print Speed: 30-60 mm/s; Max Speed: up to 130 mm/s

- Power: 110-220 VAC, 50/60 Hz

- Printer Footprint: ~30” L × 21” W × 28” H; Weight: ~38 lbs (with empty extruder)

- Includes: ceramic extruder (1000 ml), tubes, nozzles, parts kit, power supply.

Who Is This Machine For?

The Wolfpack 3DCP clay printer is positioned as a great fit for:

- Beginners in the world of ceramic 3D printing who want professional-grade results.

- Artists or makers working in studios with limited space (desktop friendly).

- Educators and schools who want to incorporate ceramic additive manufacturing into their curriculum.

- Small commercial operations (prototyping, small-batch ceramic parts) wanting a machine that balances power + compact size.

Things to Consider / Buyer Checklist

Before you buy, here are some practical considerations to keep in mind:

- Material preparation & post-processing: While you’re printing clay, you’ll still need to consider drying, firing, possibly glazing depending on your end goal.

- Workspace setup: Even though the machine is compact, ensure you have proper ventilation, access to power (110-220 VAC), and stable surface.

- Software and workflow: It uses STL files (common in 3D printing) and a web-interface. But slicing and clay-specific parameters may require tuning.

- Nozzle/flow customization: The ability to switch nozzles is great — but you’ll want to experiment with nozzle size, clay viscosity, print speed for optimal results.

- Cost vs capacity: Even though this is more affordable than large industrial clay printers, ensure the build volume and speed suit your projects.

Use Cases — What Can You Create?

Here are some inspiring ways you could use a machine like this:

- Custom pottery or ceramic art pieces with intricate geometry.

- Prototype ceramic parts for functional applications (e.g., design objects, tile systems).

- Educational labs where students explore digital fabrication with ceramic materials.

- Boutique studio production of limited-edition ceramic runs.

Final Thoughts

The Wolfpack 3DCP Clay 3D Printer offers a strong value proposition for makers and educators in the USA looking to dive into clay additive manufacturing without moving into massive industrial systems. With its direct clay extrusion, WiFi control, compact footprint and versatile nozzle options, it’s well-suited for the creative and educational market. As always, careful consideration of your workflow (design → print → drying/firing) will maximise your results.