3D printing isn’t just for plastics anymore. With clay and ceramic-based additive manufacturing gaining traction, the possibilities for artists, makers, educators, and studios are expanding rapidly. In this article, we’ll dive into what clay 3D printing is, how it works, why it matters, key benefits and challenges, and how the Wolfpack 3DCP clay printer fits into this evolving landscape.

1. What is Clay 3D Printing?

Clay 3D printing refers to the process of using a 3D printer specifically designed to extrude clay or ceramic paste layer by layer to build objects. Unlike standard FDM or resin 3D printers, these machines must handle heavier, softer, more variable materials (clay) which require special extruders, nozzles, and drying/firing workflows.

This mirrors how construction-scale concrete 3D printing works in the building industry. constructions-3d.com+1

2. How Does the Process Work?

- Material preparation: The clay must be of the right consistency (flowable yet cohesive) so it can be extruded and hold shape.

- Design & slicing: A digital 3D model (STL/OBJ) is sliced into layers, and the printer is given a path.

- Printing/extrusion: The clay extruder deposits the material layer by layer, building up the object.

- Drying/firing: After printing, the object usually needs to dry and then be fired (and optionally glazed) to become a finished ceramic piece.

- Post-process: Finishing (sanding, glazing, firing) to achieve final look and strength.

3. Why Clay 3D Printing Matters

- Creative freedom & complexity: Objects with complex geometries, internal lattice structures, or organic forms become possible.

- Material authenticity: Real clay/ceramic prints retain the material feel, texture and firing potential of traditional ceramics.

- Studio & classroom ready: Desktop-sized clay printers make this technology accessible to smaller studios, schools, and makerspaces — not just large industrial setups.

- Integration of technology + craft: It bridges traditional ceramic craft with digital manufacturing.

- By analogy: in construction, 3D concrete printing is enabling new forms, faster builds, lower waste.

4. Key Benefits

- Precision & repeatability: Digital control means consistent outputs, easier replication of forms.

- Reduced manual labour/time: Less hands-on building compared to pot-forming, wheel-throwing, or hand-laying.

- Material savings: Less waste compared to traditional subtractive ceramic methods.

- Accessibility: Artists or small studios can experiment with forms that were previously too expensive or complex.

5. Challenges & Considerations

- Material consistency: Clay flow, drying shrinkage, cracking — these are tougher than plastic.

- Post-processing: Printing is only part of the workflow — drying, firing, glazes still matter.

- Firing infrastructure: You need access to kiln or ceramic firing facilities to finish parts.

- Learning curve: Digital modelling, slicing for clay, extruder tuning require new skills.

- Size & scale limits: Desktop clay printers have build-volume limits compared to industrial machines.

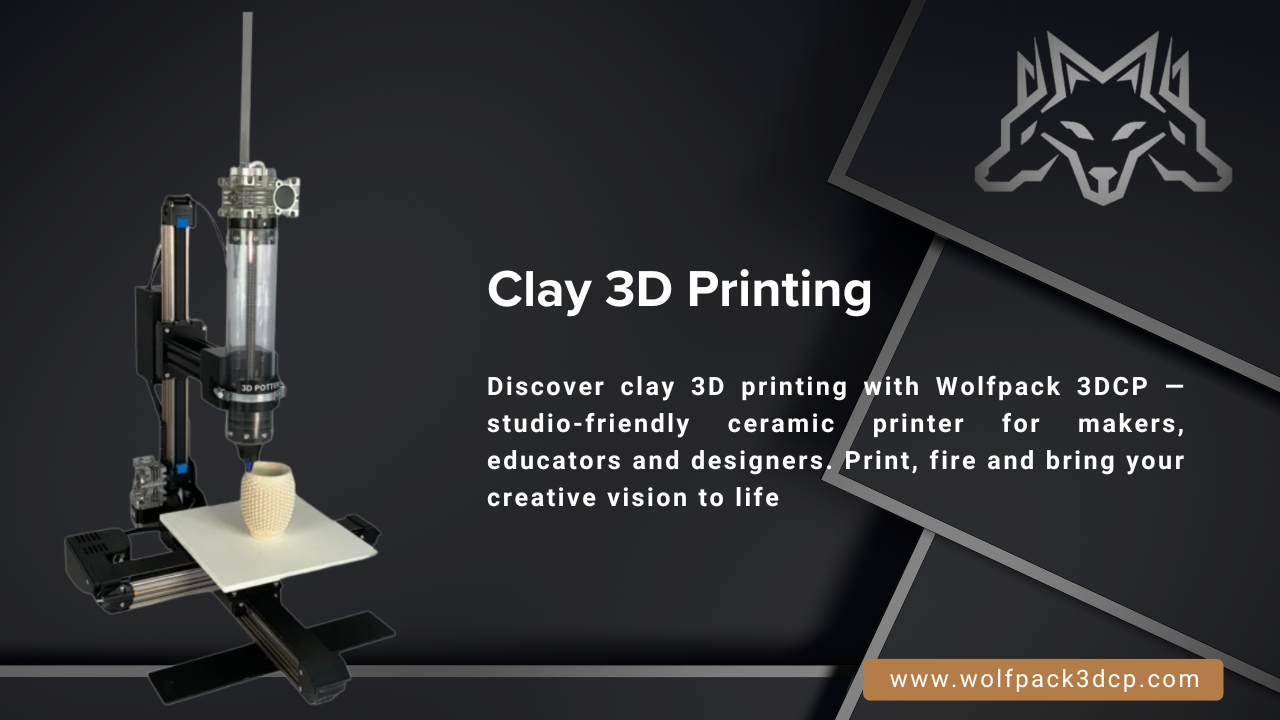

6. How the Wolfpack 3DCP Clay 3D Printer Fits In

Here’s why the Wolfpack model is a strong option for makers, educators and studios:

- Designed for clay/ceramic: Built specifically to handle clay extrusion and the demands of ceramic printing.

- Desktop-friendly form factor: Makes it viable for smaller spaces, schools, maker labs.

- Versatility: Enables experimentation with shapes, textures, and materials — from studio art pieces to design prototypes.

7. Use Cases & Applications

- Art & sculpture: Create ceramic works with complex geometry or generative forms.

- Pottery production: Short-runs of cups, vases, decorative objects with digital design.

- Education: Teaching digital making + ceramics in one workflow.

- Design prototyping: Architects, product designers exploring ceramic parts, facades or components.

8. Choosing the Right Clay 3D Printer: Buyer Checklist

Before investing, consider:

- Build volume / size.

- Clay extruder compatibility (nozzles, flow adjustment).

- Material support: types of clay (earthenware, stoneware, porcelain) you’ll use.

- Software/firmware ease of use.

- Post-process / firing workflow.

- Budget vs operational cost (kiln, materials, glazes).

9. Future Trends

- As materials improve (clay blends, faster drying), desktop clay printers will become more reliable and productive.

- Integration with multi-material printing (ceramic + metal + polymer) could open hybrid objects.

- Increased adoption in educational & design fields will push innovation and accessibility in ceramic additive manufacturing.

Conclusion

Clay 3D printing is a compelling convergence of craft, design and technology — enabling makers to push boundaries of form, texture and function. For studios, schools or creators seeking to explore digital ceramics, the Wolfpack 3DCP clay printer offers a powerful entry point. With the right workflow (design → print → dry → fire), you can unlock a new realm of creative possibilities.